Custom Optical Borofloat Glass Wafer For Electronic

Components

Material: - High-quality borofloat glass is used to manufacture these wafers

- Durable and resistant to thermal shock, ensuring long lifespan in

harsh environments

Quality: - Exceptional optical clarity with minimal distortion for precise

viewing

- Strict quality control measures ensure consistent performance and

durability of the wafer

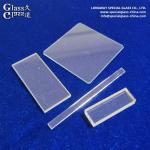

Function: - Designed to provide a clear view for various electronic components

and laser lens applications requiring high-quality glass wafers

- Borofloat glass wafers are ideal for use in precision measurement

systems, display cases, and optical instruments such as microscopes

and telescopes

Specific Application: - Ideal for various electronic components and laser lens

applications, including:

- Precision measurement systems (microscopes, spectrometers)

- Display cases (museum exhibits, retail displays)

- Optical instruments (telescopes, binoculars)

Advantages: - High optical clarity and minimal distortion for precise viewing

- Resistant to thermal shock, scratches, and chemical corrosion

- Can withstand extreme temperatures (up to 500°C) and humidity

levels

- Ideal for use in high-precision applications where accuracy is

critical.

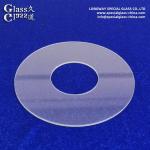

| Name | Glass disc, Glass wafer, Glass substrate, Sight glass |

| ofloat | | Diameter Tolerance | +0/-0.2 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | By Cutting,Grinding, Polishing | | Working temperature | Resisting high temperature shock | | Surface Quality | 80/50,60/40,40/20 | | Material Quality | No scratches and air bubble | | Transmission | >90% for visible light | | Chamfer | 0.1-0.5 mm x 45 degree | | Surface Coating | Available | | Usage | Photography, Lighting system, industrial area. |

|