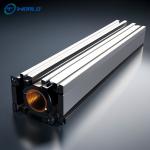

OEM Precision Heavy Duty Linear Motion Guides in a Variety of Surface Finishes

|

|

Product Description:

In today’s highly competitive manufacturing landscape, precision, durability, and smooth performance are critical factors when selecting the right components for your machinery and automation systems. One such component that plays an essential role in ensuring accurate and efficient motion is the OEM precision heavy duty linear motion guide. These guides are engineered to provide smooth, precise movement and superior load-carrying capacity, making them a popular choice in industries ranging from robotics and automotive to aerospace and heavy machinery. What sets OEM precision heavy duty linear motion guides apart is their ability to handle high loads, provide high-speed movement, and maintain precision over extended periods. Moreover, the availability of these guides in a variety of surface finishes offers additional advantages, including enhanced wear resistance, corrosion resistance, and aesthetic appeal. What Are OEM Precision Heavy Duty Linear Motion Guides?OEM (Original Equipment Manufacturer) precision heavy duty linear motion guides are custom-designed linear guides that enable smooth and controlled movement of mechanical components along a fixed path. They consist of a series of rails and rolling elements (such as ball bearings, roller bearings, or linear slides) that allow for precise linear motion. These guides are typically used in applications where heavy loads, high speeds, and precise positioning are required. Linear motion guides come in various configurations and are available in different materials such as steel, aluminum, and specialized alloys. These guides are crucial for applications where accurate positioning and smooth travel are necessary, including in CNC machinery, industrial automation, robotics, material handling systems, and more. Benefits of Using the Right Surface Finish for Heavy Duty Linear Motion Guides:

Applications of OEM Precision Heavy Duty Linear Motion Guides:

ConclusionChoosing OEM precision heavy duty linear motion guides in a variety of surface finishes offers manufacturers a range of benefits, from improved durability and corrosion resistance to enhanced aesthetics and reduced friction. The ability to customize these guides with different surface treatments ensures that they are suited for even the most demanding applications across industries like aerospace, automotive, medical devices, and more. Whether you're optimizing automated machinery, CNC equipment, or heavy-duty industrial systems, precision linear motion guides are essential for maintaining smooth and precise movement. With the right surface finish, you can extend the lifespan of your guides and keep your operations running efficiently and cost-effectively.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: Varied Surface Finishes Linear motion rails Precision Linear motion rails Heavy duty Linear motion rails |

|

Aluminum CNC Linear Motion Guideway Dual Shaft Cross Rolling Bearing |

|

OEM Precision Heavy Duty Linear Motion Guides in a Variety of Surface Finishes |

|

CNC Dual Shaft Linear Guide Slider Rail Hiwin 6mm CNC Liner Bearing SGIR |

|

HGR15 Stainless Steel Linear Guide Slider Mirror Polishing Surface |

|

CNC Steel Linear Actuator Slider , ISO9001 Sheet Metal Linear Motion Rail |

|

Stainless Steel Linear Roller Guideways , Polishing Aluminum CNC Linear Slide |