1 - 10 of 31

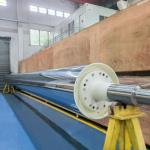

high heating exchange cooling roller

Selling leads|

High Heating Exchange Rate Cooling Roller Anti -Adhension Coating BOPP / BOPET Introduction of Anti-Adhension Cooling Roller: Anti-adhension finish ...

2025-07-29 00:23:27

|

|

...Cooling Roller Chrome Coating BOPP Introduction of Cooling Roller: Presently, the internal design of cooling rollers used in the production of bi...

2025-07-29 00:23:27

|

|

... of biaxial oriented film production lines. Its primary function is to enhance the surface adhesiveness of the film. As the film passes over the ...

2025-07-29 00:23:27

|

|

Surface Temperature Control 1℃ Chill Roller Double Shell Construction BOPP BOPET Chill Roller Basis Information : Chill rollers are widely implemented ...

2025-07-29 00:23:27

|

|

... is categorized into two distinct configurations: the double-layer single-flow and the double-layer double-flow setups. The internal medium ...

2025-07-29 00:23:27

|

|

...double-layer single-flow setting and a double-layer double-flow setting. The internal medium is water or heat transfer oil. The internal structures ...

2025-07-29 00:23:27

|

|

...Chilling Rollers. Mirror Polished Chilling Rollers are manufactured using the latest manufacturing process, obtained through rigorous scrutiny of ...

2025-07-29 00:23:27

|

|

Thousand-volt High-voltage Corona Treatment Roller Increase Film Roughness Corona Treatment Roller Production: Corona treatment roller is a kind of ...

2025-07-29 00:23:27

|

|

...Roller EVA Film Lamination Introduction of Casting Roller: Casting Roller is the main cooling roller of the Lamination System, which is used to ...

2025-07-29 00:23:27

|

|

... like LDPE, PP, EVA, EAA, LLDPE, EMA, and EMAA onto BOPP or BOPET films. Typically, this casting roller utilizes a jacketed spiral cooling water ...

2025-07-29 00:23:27

|