Metal Surface Pretreatment Equipment Spray System for Powder

Coating Production Line Surface Preparation with Spray Cleaner

The spray cleaner performs essential surface treatment prior to

powder coating application, ensuring optimal coating adhesion. Comprehensive Surface Treatment

The spray cleaner effectively:

Removes all surface contaminants from workpieces Creates a uniform phosphating film layer Enhances corrosion resistance Prepares surfaces for superior powder coating bonding

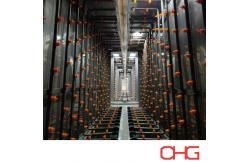

Custom-Engineered Equipment

Our systems incorporate:

Advanced technological solutions Tailored designs based on specific user requirements Adaptable configurations for various production needs

Modular System Design

Each treatment section features:

Durable spray booth enclosure Precision spray system components Integrated solution reservoir Optional heating systems (configurable per user requirements)

Spray pretreatment is a crucial step in the coating production

line, where the surface of the workpiece undergoes a thorough

cleaning and preparation process before the actual coating

application. The goal of spray pretreatment is to enhance the

adhesion and durability of the applied coating, ensuring a

high-quality and long-lasting finish. There are various types of

spray pretreatment methods used in coating production lines, and

some of the common ones include: | Degreasing | In this step, a cleaning solution is sprayed onto the surface of

the workpiece to remove any grease, oil, or contaminants that may

be present. Degreasing is essential to ensure proper coating

adhesion. | | Phosphating | Phosphating is a chemical pretreatment process where a phosphate

solution is sprayed onto the workpiece's surface. It creates a

thin, adherent phosphate coating that improves the coating's

adhesion and corrosion resistance. | | Rinsing | After each pretreatment stage, the workpiece is typically rinsed

with water to remove any remaining cleaning or pretreatment

chemicals. | | Surface Conditioning | Some pretreatment systems may include a surface conditioning step,

where the workpiece is exposed to abrasive media to create a

roughened surface. This helps improve coating adhesion, especially

for certain materials. | | Drying | Before the actual coating process, the workpiece is often dried to

ensure a clean and moisture-free surface, which is vital for a

successful coating application. |

|