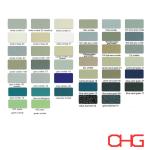

Customized Epoxy Powder Coating Powder High Gloss Semi Gloss And Non Gloss Options

|

Detailed Product Description

|

Customized Epoxy Powder Coating Powder With High Gloss Semi Gloss

And Non Gloss Options For Different Industry Requirements Epoxy Powder Coating Characteristic specific gravity: 1.4-1.8g/cm3, depends on the formula and colors. Distribution of granularity: average 30-50μm, 99%<100μm, 60-70%>32μm Application application area: high voltage static powder spray coating, friction static coating Layer thickness: 50-150μm depends on different industry requirements Coverage: 9-12m2/kg (layer thickness 60μm) Packaging and store 20kg cartoon with plastic bag inside. Away from heat sources, avoid direct sunlight, below 30ºC and dry environment. Shelf life is 24 months. Curing Low Temperature Curing: 160ºC, 20Mmin (workpiece temperature) Normal Temperature Curing: 180ºC, 20Mmin (workpiece temperature) Fast Curing: 200ºC, 10Mmin (workpiece temperature) Exterior appearance Luster: (GB/T9754-88, measure from 60 degree) High gloss type >81% Semi gloss type: 31-80% Non gloss type: 3-30% customized Appearance: flat smooth, little crinkle Mechanical Characteristic Pencil Rigidity: GB/T6739-1996 > 2H Blow test: GB/T1732-1993 50Kg.cm Cupping test: GB/9753-1988 > 6mm (depends on formula and colors) Bending test: GB/T6742-1986:2 mm Adhesive force: GB/T9286-1998:0 grade Anti-Corrosion Salt Spray Test: GB/T10125-1999: no impact on coated layer after 1000 hours and the corrosion of section is less than 2mm.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Customized Powder Coating Powder Epoxy Powder Coating Powder Custom Epoxy Powder Coating | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

Durable and Epoxy Powder Coating Powder for Friction Static Coating 9-12m2/kg Coverage 180 ordm C Normal Temperature Curing |

|

Powder Coating Powder for Coating Solutions for Various Industries with Excellent Mechanical Characteristics |

|

Customized Epoxy Powder Coating Powder High Gloss Semi Gloss And Non Gloss Options |

|

Durable and Adhesive Powder Coating Powder for Various Applications |

Email to this supplier