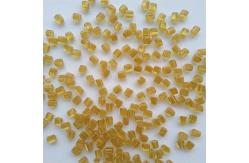

PEI Amber Conductive Poly Beads Bulk Plastic Pellets For Injection Molding

|

|

PEI Amber Conductive Raw Material Used For Optical Fiber Plugs Conductive Raw Material For Connector Parts, And High-Temperature Resistant And Flame Retardant Raw Material PEI Amber Conductive Raw Material Product Description:Excellent choice for high-performance materials In the modern industrial field, the demand for high-performance

materials is growing. Amber conductive plastics play a key role in

many industries with their unique performance advantages. TUWE

customizes various plastic conductive compounds according to

customer needs, and customizes combinations of different substrates

to meet different customer needs PEI Amber Conductive Raw Material Features:

Excellent conductivity: It has stable and good conductivity

properties, which can effectively meet the strict requirements for

material conductivity in the fields of electronics and electrical

appliances, new energy vehicles, aerospace and other fields, ensure

stable current transmission and reduce signal interference. High temperature resistance and corrosion resistance: Inheriting

the characteristics of PEI material's high temperature resistance

and corrosion resistance, it can work stably for a long time in a

high temperature environment, and is not easy to deform or degrade

performance due to temperature changes. At the same time, it can

resist the erosion of a variety of chemical substances, maintain

good physical properties in harsh chemical environments, and extend

product service life. Excellent appearance and form: The amber appearance gives it a

unique visual effect in product applications. The shape of plastic

grains is easy to process and shape, and can be made into various

complex shaped product parts through various processing processes

such as injection molding and extrusion. PEI Amber Conductive Raw Material Technical Parameters:

PEI Amber Conductive Raw Material Applications:

Electronic and electrical fields: Commonly used to manufacture

optical fiber plugs, connector components, etc. Its good electrical

conductivity ensures stable transmission of signals and ensures

efficient operation of electronic equipment; its high temperature

resistance can cope with the heat generated during operation of the

equipment, avoid damage to materials due to high temperatures, and

improve the reliability and stability of electronic and electrical

products. New energy vehicle field: It plays an important role in battery

systems and electrical connection components of new energy

vehicles. It can be used for the manufacture of battery connecting

strips, charging pile interfaces and other components to ensure the

power transmission efficiency between battery packs. At the same

time, its corrosion resistance can resist the erosion of chemical

substances such as battery electrolytes, ensuring the safety of the

automobile electrical system in complex environments. operation. PEI Amber Conductive Raw Material Customization:

Demand communication: Customers explain customization needs in

detail through email and online chat, including specific

application scenarios, performance requirements, color preferences,

size specifications and other information of the product. Scheme design: TUWE professional engineer team designs customized

product solutions for customers based on customer needs, combined

with their own technical advantages and experience. The plan covers

raw material selection, formula adjustment, production process

planning, etc., and communicates with customers to confirm to

ensure that the plan meets customer expectations. Sample preparation: After the plan is determined, the company makes

samples according to the plan. Use advanced production equipment

and superb craftsmanship to strictly control the quality of samples

to ensure that the samples can accurately reflect the performance

and specification requirements of customized products. After the

production is completed, the samples will be sent to the customer

in a timely manner for testing and evaluation. Mass production: After the customer is satisfied with the samples

and confirms them, the two parties sign a formal contract to

determine the order quantity, price, delivery time and other

details. Yirong Plastic started the batch production process, used

professional intelligent production lines, and carried out

production in strict accordance with production standards and

quality control systems to ensure the consistency and stability of

product quality. Quality inspection and delivery: During the production process,

professional quality inspection personnel strictly inspect each

batch of products to ensure that the products meet customization

requirements and quality standards. After passing the inspection,

the goods will be delivered according to the logistics method

required by the customer, the products will be delivered to the

customer in a timely manner, and logistics tracking services will

be provided to allow the customer to know the product

transportation status at any time. PEI Amber Conductive Raw Material Support and Services:Our Conductive Compounds are designed to provide optimal electrical conductivity in a variety of applications. Our technical support team is available to assist with any questions regarding product selection, application methods, and troubleshooting. We also offer custom formulation services to meet specific conductivity requirements for unique applications. Our services include:

PEI Amber Conductive Raw Material Packing and Shipping:Product Packaging: The Conductive Compounds product is packaged in a sturdy, sealed container to protect the contents from damage during transport and storage. The container is labeled with the product name, description, and important safety information. Shipping: The Conductive Compounds product is shipped via ground transportation in compliance with all applicable regulations. The product is carefully packaged to prevent damage during shipping and is labeled with the necessary shipping information, including the product name, quantity, and handling instructions. |

||||||||||||||||||

| Product Tags: PEI poly beads bulk plastic poly beads bulk PEI bulk plastic pellets for injection molding |

|

PC ABS Carbon Fiber Conductive Masterbatch Moldable Plastic Beads For Electronics Devices |

|

Thermoplastic Conductive Compounds ABS Antistatic Bulk Plastic Pellets |

|

PEI Amber Conductive Poly Beads Bulk Plastic Pellets For Injection Molding |

|

High Impact Conductive Compounds POM ABS Plastic Pellets |

|

Natural Modified ABS Plastic Pellets Bulk Masterbatch OEM |

|

Transparent Conductive Compounds Antistatic ABS Plastic Pellets Bulk For Electrical Enclosures |