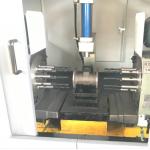

High-precision Double-sided Multi-hole CNC Drilling And Tapping Machine

|

|

Double-sided multi-hole drilling machine

The main features of the double-sided multi-hole drilling machine are high efficiency, precision and versatility. This type of drilling machine can drill holes on both sides of the workpiece at the same time, significantly improving processing efficiency and reducing the time to disassemble the workpiece. It usually adopts a horizontal design, which makes the operation more stable and suitable for multi-hole processing. It can complete the processing of multiple holes at one time and improve production efficiency.

Main features 1. Efficiency: The double-sided multi-hole drilling machine can use

multiple drill bits to process both sides of the workpiece at the

same time, without manually flipping the workpiece, which greatly

shortens the processing time and improves the processing

efficiency.

Application areas 1. Casting valves: various valves, such as gate valves, butterfly valves, check valves, etc. 2. Casting water pumps: water pumps of various calibers and shapes. 3. Fire protection industry: water supply and drainage facilities such as fire hydrants. 4. Pipe fittings industry: various flange elbow pipe fittings.

Details

Processed product

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Drilling CNC Tapping Machine Tapping CNC Drilling Machine Tapping Drilling CNC Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Customized High Precision Double-sided Multi-hole Multi-axis CNC Drilling Machine |

|

High Precision 2-sided Multi-hole CNC Drilling Machine Side Hole Drilling Machine |

|

High-precision Double-sided Multi-hole CNC Drilling And Tapping Machine |

|

High-precision Double-sided Multi-hole Multi-axis CNC Side Hole Drilling Machine |

|

Industrial Double-Face Drilling Equipment PLC Programming For Valve Process |

|

Double-Sided Multi-Hole Drilling Machine For Valve Flanges Tees High-Speed PLC Control |