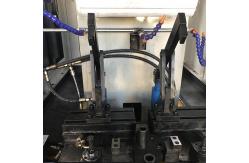

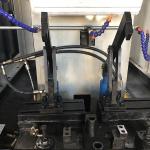

CNC Single-sided Multi-head Milling, Drilling And Tapping Machine

Tools

The CNC rotary cutter head vertical tapping, drilling, milling and

grinding machine is a multi-functional CNC machine tool that

integrates multiple processing functions such as tapping, drilling,

milling and grinding, and is equipped with a rotatable cutter head,

which can achieve multi-angle processing.

1. Structure

Vertical design: the spindle is arranged vertically, and the

workpiece is fixed on the workbench.

Rotating cutter head: the cutter head can rotate at multiple angles

2. CNC system

CNC control: automatic processing is achieved through computer

programming

Multi-axis control: usually has three axes (X, Y, Z) or more axes

3. Function

Tapping: automatic tapping function, suitable for internal thread

processing.

Drilling: can perform drilling of various diameters and depths.

Milling: supports multiple milling operations such as planes,

contours, grooves, etc.

Grinding: has grinding function, suitable for high-precision

surface processing.

Multi-angle processing: the rotary cutter head supports multi-angle

processing, reducing the number of times the workpiece is

re-clamped.

4. Advantages

High efficiency: multiple processes are completed in one clamping,

reducing auxiliary time.

High precision: The CNC system ensures machining accuracy and

consistency.

Flexibility: Adapt to different machining requirements through

programming.

Multi-angle machining: The rotary cutter head supports multi-angle

machining, reducing the number of times the workpiece is

re-clamped.

Multi-function integration: Integrates tapping, drilling, milling

and grinding to meet a variety of machining needs.

The CNC rotary cutter head vertical tapping, drilling, milling and

grinding machine integrates tapping, drilling, milling and grinding

functions, has multi-angle machining capabilities, and is suitable

for high-precision and high-efficiency complex parts machining. It

is widely used in molds, aerospace, automobiles, precision parts

and other fields.

| Project | Machine tool specifications | YCZG-SKZG40 |

| Technical specifications | Z-axis travel(mm) | 700 |

|

| X-axis travel(mm) | 500 |

| Y-axis travel(mm) | 500 |

| Tool connection method | BT40 |

| Processing accuracy | Position accuracy | ≤0.015/3000 |

| Surface roughness | 3.2 |

| Spindle drive | Transmission mode | Stepless speed change |

| | Spindle speed range (r/min) | 0-1000 |

| | Spindle motor model | 5.5KW servo |

| CNC control system (optional) | Nanjing Huaxing-servo system Guangzhou CNC-servo system |

| Feeding mode | Servo motor | 7.7N.m |

| Machine tool appearance | Fullprotection (Length×width ×height)( mm) | 2760×2200×2430 |

| Machine weight (KG) | 3000 |

Machine picture