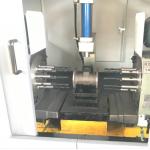

Valve Fittings PLC Control Two Head Multi Hole Drilling Machine YC II Z200HT

|

|

Valve Fittings PLC Control Multi-Hole Two Head Drilling Machine

Valve Fittings PLC Control Multi-Hole Two Head Drilling Machine is an efficient machine tool specifically designed for drilling holes on both sides of a workpiece simultaneously. It significantly improves production efficiency through double-sided synchronous processing, especially suitable for parts that require processing multiple holes on both sides of the workpiece. This type of machine tool is widely used in industries such as automobiles, aerospace, engineering machinery, and home appliances.

Aerospace: Construction Machinery: Home appliance manufacturing: Electronic industry:

Maintenance

Application area

Processed Products

Picture

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: multi hole drilling machine yc ii z200ht plc side hole drilling machine plc multi hole drilling machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Customized High Precision Double-sided Multi-hole Multi-axis CNC Drilling Machine |

|

High Precision 2-sided Multi-hole CNC Drilling Machine Side Hole Drilling Machine |

|

High-precision Double-sided Multi-hole CNC Drilling And Tapping Machine |

|

High-precision Double-sided Multi-hole Multi-axis CNC Side Hole Drilling Machine |

|

Industrial Double-Face Drilling Equipment PLC Programming For Valve Process |

|

Double-Sided Multi-Hole Drilling Machine For Valve Flanges Tees High-Speed PLC Control |