3D Printing Nickel In625 Metal Powder for Aerospace Turbine

Components

1. Introduction

Nickel-based superalloys, particularly Inconel 625 (In625),

are widely used in aerospace applications due to their

exceptional high-temperature strength, corrosion resistance,

and fatigue resistance. Additive Manufacturing (AM), or 3D

printing, enables the production of complex aerospace turbine

components with reduced material waste and improved design

flexibility.

This detailed description covers the properties of In625 metal

powder, 3D printing processes, post-processing, and aerospace

turbine applications.

2. Inconel 625 (In625) Metal Powder Properties

In625 is a nickel-chromium-molybdenum superalloy with the

following key characteristics:

Chemical Composition (ASTM B443)

| Element | Composition (wt.%) |

|---|

| Nickel (Ni) | ≥ 58.0 |

| Chromium (Cr) | 20.0 - 23.0 |

| Molybdenum (Mo) | 8.0 - 10.0 |

| Iron (Fe) | ≤ 5.0 |

| Niobium (Nb) | 3.15 - 4.15 |

| Titanium (Ti) | ≤ 0.40 |

| Aluminum (Al) | ≤ 0.40 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

Mechanical & Thermal Properties

Tensile Strength: 930 MPa (at room temperature)

Yield Strength: 517 MPa

Elongation: 42.5%

Density: 8.44 g/cm³

Melting Point: 1290 - 1350°C

Oxidation Resistance: Excellent up to 980°C

Corrosion Resistance: Resistant to pitting, crevice corrosion,

and saltwater environments

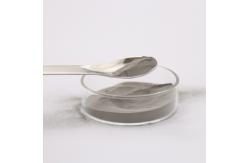

Powder Characteristics for 3D Printing

Particle Size Distribution: 15 - 45 µm (for LPBF) or 45 - 106

µm (for DED)

Morphology: Spherical (for optimal flowability)

Powder Production Method: Gas Atomization (Argon or Nitrogen)

Flowability: ≤ 25 s/50g (Hall Flowmeter test)

Apparent Density: ≥ 4.5 g/cm³

3. 3D Printing Processes for In625 in Aerospace Turbines

The most common metal 3D printing methods for In625

include:

A. Laser Powder Bed Fusion (LPBF / SLM)

B. Directed Energy Deposition (DED / LENS)

C. Electron Beam Melting (EBM)

4. Post-Processing for Aerospace Turbine Components

To meet stringent aerospace

requirements, post-processing is essential:

A. Heat Treatment

Stress Relief: 870°C for 1 hour (air cooling)

Solution Annealing: 1150°C for 1 hour (water quenching)

Aging (if needed): 700 - 800°C for 8 - 24 hours

B. Hot Isostatic Pressing (HIP)

C. Machining & Finishing

CNC Machining: For tight-tolerance features

Surface Finishing: Electrochemical polishing or abrasive flow

machining for smoother surfaces

Non-Destructive Testing (NDT): X-ray CT, ultrasonic testing,

or dye penetrant inspection

5. Aerospace Turbine Applications

3D-printed In625 is used in critical turbine components,

including:

Turbine Blades & Vanes (with internal cooling channels)

Combustor Liners (heat and corrosion resistance)

Exhaust Nozzles (high-temperature stability)

Fuel Nozzles (GE Aviation’s LEAP engine uses 3D-printed In625)

Repair of Worn Turbine Parts (via DED)

Benefits Over Traditional Manufacturing

✔ Weight Reduction (lattice structures & topology

optimization)

✔ Faster Production (no need for complex tooling)

✔ Improved Performance (optimized cooling channels)

✔ Material Savings (near-net-shape manufacturing)

6. Challenges & Future Trends

Challenges:

High Cost of In625 Powder

Residual Stress & Distortion (requires proper heat

treatment)

Powder Reusability Limits (typically 5 - 10 cycles before

degradation)

Future Trends:

AI-Driven Process Optimization (for defect-free printing)

Hybrid Manufacturing (combining AM with CNC machining)

New Alloy Development (higher-temperature variants)