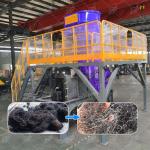

Pyrolysis Tire Wire Shredding Line Tire Steel Wire Crusher Waste Steel Pre Crusher

|

|

Pyrolysis Tire Wire Shredding Line Tire Steel Wire Crusher Waste Steel Pre Crusher Products Description Steel Wire Vertical Crusher is a crushing equipment with a vertical

spindle design. Through the cooperation of vertical rotating

cutters and fixed lining plates, it shears and impacts materials

containing steel wires and separates steel wires from other

materials. Its typical features are "vertical spindle arrangement

and cylindrical cavity". It is often used for crushing pretreatment

of waste tires, rubber products and metal composite materials, with

the advantages of small footprint and high crushing efficiency. Working principle of stee wire vertical crusher: Pyrolysis waste tire steel wire crushing production line: The pyrolysis waste tire steel wire crushing production line is a special recycling system for tire waste after pyrolysis treatment. Through the process chain of "pyrolysis desorption-crushing separation-purification and recycling", the pyrolysis tire steel wire is efficiently separated from carbon black and rubber residues to achieve the recycling of metal resources. Compared with traditional crushing processes, this production line has the advantages of strong environmental protection, high metal recovery rate and low energy consumption, and is especially suitable for large-scale waste tire processing scenarios. Process flow of pyrolysis waste tire steel wire crushing production line: 1. Feeding system: Technical advantages of pyrolysis waste tire steel wire crushing

production line:

Tire stee wire vertical crusher is also a metal crusher, and is

also suitable for the following materials: √ Iron cuttings,sheet iron, sheet steel √ Copper cuttings, sheet copper, Steel cuttings √ Scrap iron bar, Waste steel wire √ Waste wire, Waste steel pipe √ Scrap metal, Scrap iron pipe √Scrap metal, Scrap steel, Scrap iron, Scrap aluminum, Scrap

radiator, Scrap copper, paint drums, diesel drums, thin iron

sheets, car shells, metal briquettes, metal plate scraps etc. Other Metal Recycling Machine

Scrap Metal Shredding & Crushing Line 1.metal recycling line adopts two-shaft metal shredder, hammer crusher for crushing the scrap metal. 2.Use Dust collector and special structures to remove the fine particle and dust during the crushing period. 3.The scrap metal recycling equipment separates the ferrous metal by a magnetic separator. 4.(Optional)Eddy current separator is adopted by the waste recycling machine to separate the non-ferrous metal from nonmetal materials. Core equipment:Double-shaft shredder,Hammer crusher,Magnetic separator.

Successful Project

|

||||||||||||||

| Product Tags: Pyrolysis Tire Wire Shredding Line Waste Tire Wire Shredding Line |

|

Pyrolysis Steel Wire Crushing And Washing Line Tire Steel Wire Crusher Scrap Steel Wire Shredder For Metal Recycling |

|

Tire Stee Wire Crusher Scrap Metal Waste Steel Pre Crusher Easy Operation |

|

Pyrolysis Tire Steel Wire Crusher Waste Steel Pre Crusher Scrap Metal Steel Wire Recycling Machine |

|

Pyrolysis Tire Wire Shredding Line Tire Steel Wire Crusher Waste Steel Pre Crusher |

|

Waste Home Appliance Recycling Machine Waste Home Appliance Plastic Crushing Recycling Machine |

|

Scrap Home Appliance Plastic Metal Crusher Waste Home Appliance Recycling Machine |