3000L/H Refuse Derived Fuel Plant Briquetting Machine For Used Clothing

|

|

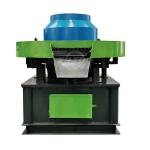

Plant for the Production of Refuse Derived Fuels (rdf) Products Description RDF briquetting machine is a special equipment that processes

biomass raw materials (such as domestic garbage, straw, sawdust,

agricultural and forestry waste, etc.) into high-density solid fuel

blocks through mechanical compression molding process. The

equipment compresses the crushed biomass raw materials in the mold

through hydraulic or mechanical pressure to make regular block

fuel. It has the characteristics of high calorific value, full

combustion, and easy storage and transportation. It can replace

traditional fossil fuels and is widely used in industrial boilers,

biomass power plants and civil heating. It is an important

environmental protection equipment for realizing waste resource

utilization. Details Images Domestic garbage, industrial solid waste, paper-making waste, waste

from water washing plants, textile waste, leather waste, ragwaste,

water plant sludge, industrial sludge, etc. Main Application The raw materials used come from landfills, garbage sorting plants,

industrial solid waste treatment plants, paper mills, chemical

plants, paper slag washing plants, scrap steel plants, textile

mills, leather factories, waste clothing treatment plants, sewage

treatment plants, industrial sludge treatment plants, industrial

park solid waste disposal centers, environmental protection

industrial parks, and garbage recycling companies. HOW TO MAKE RDF BRIQUETTES FROM CITY WASTE Pre-shredder – Shred waste to a size below 80mm Rotary Screener, Air Separator – Separate combustibles waste by size and density. Shredder – Shred waste to a size below 40-60mm. Buffer Bin – The material is conveyed to the buffer Bin after sorting and shredding. The speed is adjusted against the briquetting machine automatically. Briquette Press – 50% energy saving, fast punch, high output, and the molding is less affected by moisture content. Conveying System – The whole line is sealed under a pulse dust removal system, which is efficient and reliable for dust removal and improves the operating environment. Intelligent Control System – All controls under the PLC touch screen. Safety – The shredder and dust collector is equipped with a spark detection system, which actively detects the spark during the shredding process and eliminates fire hazards. Manufacturing Technique

Feedback Final Products: |

||||||||||||||||||||

| Product Tags: 3000L/H Refuse Derived Fuel Plant Refuse Derived Fuel Briquetting Machine Used Clothing Briquetting Machine |

|

Msw Srf Rdf Briquette Machine Cloth Plastic Fabric RDF Briquetting Machine MSW To RDF SRF Briquette Plant |

|

RDF Making Machine Garbage Briquette Compression Making Biomass Roller Press Rdf Briquetting Machine |

|

Fuel Solid Waste Rdf Briquette Machine 3000L/H Rice Husk Briquette Machine |

|

Industrial Solid Waste Compactor 150kg/H-250kg/H RDF Processing Plant |

|

3000L/H Refuse Derived Fuel Plant Briquetting Machine For Used Clothing |

|

Complete Municipal Solid Waste Wood Refuse Derived Fuel Rdf Pellet Factory with Ce |