5mm PU Screen Panel 8.0mm Mesh for Gravel with Quick-Clamp

|

|

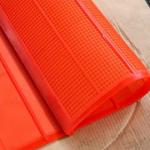

5mm Thickness PU Screen Panel 8.0mm Mesh for Gravel with Quick-Clamp Design

High-frequency PU fine mesh for silica sand processing thrives in

high-speed vibrating screens, where its 0.045–1.0mm mesh captures

even the finest particles. The mesh’s density (1.25g/cm³) ensures

uniform aperture sizing, while the 35–40% open area balances

throughput with precision—key for producing glass-grade silica. Its

compatibility with Derrick Stack Sizer Machines makes it a

plug-and-play upgrade.

1) Product Description of 5mm Thickness PU Screen Panel 8.0mm Mesh for Gravel with Quick-Clamp Design

The 0.075mm aperature High-Efficiency Polyurethane Urethane Screens working 6-12 months are designed to withstand the rigorous demands of mining operations. Made from high-quality polyurethane, these screens offer exceptional durability and wear resistance. They are ideal for separating and sizing minerals, aggregates, and other materials in mining and quarry applications.

2) Specification of 5mm Thickness PU Screen Panel 8.0mm Mesh for Gravel with Quick-Clamp Design

3) HUATAO focus to supply 5mm Thickness PU Screen Panel 8.0mm Mesh for Gravel with Quick-Clamp Design

Constructed from high-density polyurethane, this mesh resists abrasion from sharp sand particles, lasting 8x longer than metal in continuous use. Its low-maintenance design eliminates the need for frequent cleaning, while the steel-encapsulated edges prevent warping under high-frequency vibration. For silica producers, this translates to reduced labor costs and increased production uptime.

4) Images of Polyurethane Fine Screen Mesh include:

A close-up of the Polyurethane screen Mesh hooks showing :

A photo of the Polyurethane Fine screen Mesh in use in a slica Sand application.

5) Factory Production Processing of High-Performance Urethane Screen panels

The manufacturing of high-frequency polyurethane screen mesh involves advanced techniques to ensure precision, durability, and optimal performance. Below is a detailed overview of the production workflow:

1. Material Preparation: elasticity requirements. Additives such as UV stabilizers and anti-aging agents are blended to enhance longevity in harsh environments. 2. Mold Design & Fabrication: wedge-shaped slots). Mold surfaces are polished to a mirror finish to ensure smooth demolding and dimensional accuracy. 3. Casting & Curing: The liquid polyurethane mixture is vacuum-degassed to eliminate air bubbles. It is then poured into preheated molds and subjected to controlled-temperature curing (80–120°C) in hydraulic presses. This step ensures uniform density and structural integrity. Post-curing thermal treatment further enhances tensile strength and chemical resistance. 4. Demolding & Trimming: prevent delamination during high-frequency vibrations. 5. Quality Control: Aperture Verification: Laser scanners measure aperture sizes (e.g., 0.045mm ±0.005mm) and open area ratios (35%–40%). Durability Testing: Simulated high-frequency vibration cycles (up to 3,600 RPM) assess fatigue resistance. Material Certification: Shore hardness (85–95A), tear strength, and chemical compatibility are validated per ISO 9001 standards. 6. Surface Treatment (Optional): inspection needs. 7. Packaging & Logistics: accommodated seamlessly.

HUATAO Hot-Selling Polyurethane Product List as below:

|

||||||||||||||||||||||||||

| Product Tags: 5mm PU gravel screen panel 8.0mm mesh polyurethane screen quick-clamp PU screen for gravel |

|

0.5mm Wear-Resistant PU Fine Mat for Wet/Dry Use |

|

1040x700mm 0.045mm Orange Polyurethane Screen for Glass Raw Materials |

|

|

Ultra-Fine PU Mesh 0.045mm for Semiconductor Sand Wastewater Treatment |

|

Red PU Screen Mat 5.0mm Mesh for Coarse Aggregate |

|

Polyurethane Fine Mesh Screen 0.045mm for High-Purity Silica |

|

5mm PU Screen Panel 8.0mm Mesh for Gravel with Quick-Clamp |