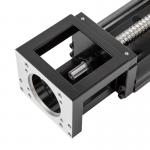

Dust proof PCB belt series linear modules supporting ultra

long stroke expansion

The scope of application of PCB belt series linear modules includes

workpiece transfer devices in production lines, adhesive film

cutting devices, transfer devices between CNC machining machines,

and more. The applicable industries cover TFT-LCD liquid crystal

panel equipment, solar energy equipment, food packaging equipment,

and CNC machining equipment. The types of PCB belts include

cleanroom belts and rubber belts.

Synchronous belt drive has obvious advantages: it adopts PM-type

high-tension toothed belts with a transmission efficiency of 98%,

and the maximum linear speed can reach 2m/s (compared to only 1m/s

for traditional screw slides). Paired with lightweight aluminum

alloy sliders, the dynamic response time is shortened to 0.4s,

which can significantly improve sorting and handling efficiency.

In terms of stroke expansion, its standard stroke ranges from 50mm

to 3500mm. Ultra-long stroke extension can be achieved through

guide rail splicing technology, without worrying about the critical

speed limitation of traditional screws. It is particularly suitable

for long-distance operation scenarios such as logistics conveyor

lines and three-dimensional warehouse shuttle cars.

| ※ Basic specifications PCB17 |

| Specification | Repetitive positioning accuracy | ±0.08 |

| Lead mm | 40 |

| Maximum speed mm/s | 2000 |

|

|

|

| Freeze thrust(N) | 204 |

| Standard stroke mm | 20-3050mm/50 interval |

| Max load (kg) | Horizontal | 45 |

| Vertical | - |

| Component | AC servo motor capacity | 400 |

| Belt width | 30 |

| High rigidity linear slider | W20×H15 |

| Origin sensor plug-in | PM-T45(NPN) |

Contact us for complete product information.