IP65 Dust Proof Linear Motor Nanometer Level Precision

Maintenance Free Core Value:

Simplifies mechanical structure, enhances transmission efficiency,

breaks through the precision and speed bottlenecks of traditional

transmission, and is suitable for high-end automation scenarios

requiring direct drive.

Typical Application Fields

- Industrial Manufacturing:

CNC machines (XYZ axis direct drive), laser processing equipment

(high-speed cutting trajectory control), semiconductor wafer

inspection platforms (nanometer-level positioning). - Medical & Research:

MRI scanner beds, surgical robot arms, spectroscopic analysis

instruments (precision displacement adjustment). - Rail Transit & Logistics:

Maglev train traction systems, intelligent warehouse high-speed

sorting lines (sorting speed > 200 pieces/minute). - Consumer Electronics & New Energy:

Mobile phone screen laminating machines, lithium battery electrode

cutting equipment, photovoltaic module string welders

(high-precision positioning).

Core Features

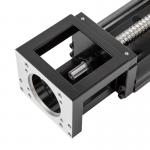

High Rigidity & Compact Structure

The LMA series integrates the sliding seat with the rotor, adopts

embedded guide rails designed in an aluminum profile body, and

integrates a grating scale for position feedback. This makes the

entire module highly compact and rigid, offering users size

optimization for specific thrust requirements. Long Stroke

The LM series has a maximum standard stroke of 5,000 mm, and

ultra-long strokes can be customized according to customer needs. Multi-Mover Slides

Full-range linear motors can be equipped with multi-mover slides

and controlled individually. Customization

Linear motors can be customized for different customer

applications, including mounting hole positions, output methods,

appearance colors, and other custom designs. | Type | ParameterMotor | Resolution(μm)

[Max speed](m/s) | Peak thrust(N) | Continuous thrust(N) | Maximum load(kg)※1 | Moving part weight(kg)※2 | Repeatable positioning accuracy(μm) | | LMA-60 | A | 1[2];0.5[1.4];0.1[1] | 176 | 44 | 5 | 0.6 | ±5 | | LMA-60 | B | 1[2];0.5[1.4];0.1[1] | 268 | 67 | 10 | 0.85 | ±5 | | LMA-90 | A | 1[2];0.5[1.4];0.1[1] | 240 | 120 | 12 | 1.5 | ±5 | | LMA-90 | B | 1[2];0.5[1.4];0.1[1] | 360 | 180 | 18 | 2.1 | ±5 | | LMA-120 | A | 1[2];0.5[1.4];0.1[1] | 400 | 200 | 20 | 4 | ±5 | | LMA-120 | B | 1[2];0.5[1.4];0.1[1] | 600 | 300 | 30 | 5.5 | ±5 |

| Rotor | Valid stroke(mm) | Reduce the stroke with each

additional slide(mm) | Starting base length(mm) | Peak force(N) | Sustained force(N) | Rail specification | Number of sliders | Maximum load(Kg) | Rotor part weight(Kg) | Repeatable positioning

accuracy (μm) | | SL5003S | Base length-200 | 150 | 300 | 105 | 60 | W15 | 2 | 7 | 2 | ±5(Magnetic scale)±2(Grating ruler) | | SL5006S | Base length-250 | 200 | 300 | 210 | 120 | 4 | 15 | 3 | | SL5009S | Base length-300 | 250 | 396 | 315 | 180 | 4 | 23 | 3.9 | | Rotor | Valid stroke(mm) | Reduce the stroke with each

additional slide(mm) | Starting base length(mm) | Peak force(N) | Sustained force(N) | Rail specification | Number of sliders | Maximum load(Kg) | Rotor part weight(Kg) | Repeatable positioning

accuracy(μm) | | SL8006 | Base length-260 | 210 | 396 | 400 | 200 | W15 | 4 | 25 | 4 | ±5(Magnetic scale)±2(Grating ruler) | | SL8009 | Base length-310 | 260 | 396 | 600 | 300 | 4 | 35 | 5 | | SL8012 | Base length-360 | 310 | 492 | 800 | 400 | 6 | 45 | 6.6 | | Rotor | Valid stroke(mm) | Reduce the stroke with each

additional slide(mm) | Starting base length(mm) | Peak force(N) | Sustained force(N) | Rail specification | Number of sliders | Maximum load(Kg) | Rotor part weight(Kg) | Repeatable positioning

accuracy(μm) | | SL8009 | Base length-320 | 260 | 396 | 600 | 300 | W20 | 4 | 45 | 6.6 | ±5(Magnetic scale)±2(Grating ruler) | | SL8012 | Base length-370 | 310 | 492 | 800 | 400 | 6 | 60 | 8.8 | | SL8015 | Base length-420 | 360 | 492 | 1000 | 500 | 6 | 75 | 10.1 |

|