Faster Long High Speed Stroke Slide Table Precision

Efficiency

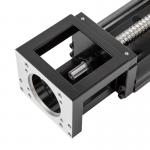

PCB Belt Series Linear Modules

Application Scope

Designed for industrial automation, the PCB Belt Series Linear

Modules are specialized in:

- Workpiece line change devices in production lines

- Adhesive film cutting devices

- Material handling systems between CNC machining centers

These modules are widely adopted across industries including:

- TFT-LCD liquid crystal panel manufacturing equipment

- Solar energy production systems

- Food packaging machinery

- CNC machining equipment

Belt Types

Available in two configurations:

- Dust-free belts (suitable for cleanroom environments)

- Rubber belts (designed for high-abrasion or general industrial

applications)

Advantages of Synchronous Belt Drive

- High-Efficiency Transmission: Utilizes PM-type high-tension toothed belts with a transmission

efficiency of 98%, achieving a maximum linear speed of 2m/s—twice

that of traditional lead screw slides. Combined with lightweight

aluminum alloy sliders, the dynamic response time is reduced to

0.4s, significantly enhancing sorting and handling efficiency.

- Unlimited Stroke Expansion: With a standard stroke range of 50–3,500mm, the modules support

ultra-long stroke extension via guide rail splicing technology.

This eliminates the critical speed limitations of traditional lead

screws, making them ideal for long-distance applications such as

logistics conveyor lines and AS/RS (automated storage and retrieval

system) shuttles.

Technical Specifications

| Feature | Detail |

|---|

| Drive Type | Synchronous belt (PM-type high-tension) |

| Maximum Speed | 2m/s |

| Standard Stroke Range | 20–3,500mm (customizable via splicing) |

| Load Capacity | Up to 150kg (horizontal installation) |

| Environmental Adaptability | Dust-free (ISO Class 5 compliant) and general industrial versions |

Professional Applications

In TFT-LCD panel production, these modules enable precise workpiece

transfer between bonding and inspection stations with dust-free

belts ensuring cleanroom compatibility. For solar energy equipment,

the rubber belt variant withstands high-temperature environments

during panel lamination, while their high-speed capability

accelerates throughput in CNC machining workflows.

Designed for reliability and scalability, the PCB Belt Series

optimizes material flow in automated systems, balancing speed,

precision, and environmental resilience across diverse industrial

sectors.

| ※ Basic specifications PCB14 |

|

| Specification | Lead(mm) | 40 |

| Max speed(mm/s) | 2000 |

| Max speed (kg) | Horizontal | 25 |

| Vertical | - |

| Rated thrust (N) | 100 |

| Standard stroke(mm) | 20-3050mm/50 interval |

| Component | AC servo motor capacity | 200 |

| Belt width | 25 |

| High rigidity linear slider | W15×H12.5 |

| Origin sensor Plug | PM-T45(NPN) |