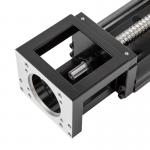

Designed for industrial automation, the EGT Series synchronous belt

slides are high-performance linear motion modules centered on the

design philosophy of "dual-guide rail precise guiding + high-load

bearing capacity + flexible mounting." They perfectly adapt to

complex mechanical structures such as linear gantries and

cantilever electric cylinders, providing stable and reliable linear

motion foundations for scenarios like logistics sorting, automotive

part handling, and electronic component mounting. Their key

highlights include a 5000mm ultra-long stroke, ±0.08mm repeat

positioning accuracy, and flexible four-side motor mounting,

redefining the versatility and adaptability of basic-axis slides. Linear Gantry Systems

In automotive assembly workshops, EGT slides serve as the X-axis

(3000mm stroke) and Y-axis (2000mm stroke) in component handling

gantries. With a 100kg load capacity, they effortlessly carry heavy

components like gearboxes. The dual-guide rail design ensures no

deflection under gantry span, while ±0.08mm accuracy meets the

positioning requirements for bolt holes. Cantilever Electric Cylinders

In 3C electronics pick-and-place machines, EGT slides function as

the X-axis (1000mm stroke) in cantilever mechanisms. The

side-mounted motor design saves 50% vertical space, while

anti-tipping torque characteristics ensure no offset under

single-side loading (e.g., nozzle heads), enabling precise

placement of 0402 components. Logistics Sorting Lines

In e-commerce warehouse automated sorting systems, EGT slides

(5000mm stroke) act as main conveying axes. With a high speed of

2.5m/s and ±0.08mm accuracy, they drive sorting carts to achieve

rapid positioning and delivery of parcels, improving efficiency by

35% compared to traditional chain conveyors.

Flexible Motor Mounting

Motors can be installed on any of the four sides of the cylinder

and easily converted as needed, offering maximum layout flexibility

for complex automation setups. Space-Saving Design

Proximity switches can be embedded within the profile grooves,

optimizing space utilization and simplifying cable management in

compact equipment. Precise Guidance & High Load Capacity

The dual-guide rail system ensures superior linear guidance and

stability, with robust load-bearing capabilities that make it ideal

for heavy-duty applications in gantries and cantilever structures.

| Standard motor output(W) | 200 | 400 | | Rated torque(N ·m) | 0.64 | 1.27 | | Repeatable positioning accuracy(mm) | ±0.08 | | Max stroke(mm) | 100-5000mm/interval 50mm | | Timing belt specification | 15×3(lead 78mm) | | Reduction ratio | No | 3:1 | / | No | 3:1 | / | | Max speed(mm/s) | 3900 | 1300 | / | 3900 | 1300 | / | | Max horizontal load(kg) | 4 | 12 | / | 8 | 15 | / | | Max load | EGT70:12 | | EGT70L:15 | | Basic weight(Omm stroke kg) | EGT70:3.67 | EGT70L:4.08 | | Increase weight(per 100mm stroke kg) | 0.34 | | Magnetic reed switch | CS1-D-1M contact type,wire length 1m/CS1-DN-3 contactless

transistor NPN type,

wire length 3m/CS1-DP-3M contactless transistor PNP type,wire

length 3m | | Photoelectric switch | PM-T45 | NPN type wire length 1M | | PM-T45-P | PNP type wire length 1M | | Briquettes | Page 140 for details |

|