|

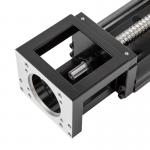

High Speed Long Stroke Synchronous Belt Slide Table with Precise Positioning As a core transmission component in industrial automation, the PTB Synchronous Belt Slide establishes a new performance benchmark for mid-to-high-end linear motion modules with its technical core of "high-load, ultra-high-speed, strong-thrust". Through innovative integration of high-rigidity structures and efficient transmission systems, it achieves three breakthroughs: 200KG horizontal dynamic load capacity, 2311mm/s ultra-high speed, and 1126N strong thrust, with a full stroke range of 50-4000mm to serve rigorous scenarios such as logistics sorting, automotive assembly, and electronic component mounting. The PTB Slide drives sorting systems at 2311mm/s ultra-high speed, effortlessly handling full cartons with its 200KG load capacity. Its 1126N thrust enables millisecond-level switching of sorting baffles, increasing parcel processing capacity from 2,500 to 8,000 pieces per hour – a 3x efficiency leap. With a dual-guide high-rigidity design and 200KG load capacity, it stabilizes engine block transportation across workstations, achieving ±0.1mm positioning accuracy for bolt hole alignment, and providing reliable support for automotive powertrain assembly. In FPC flexible board pressing, its 1126N strong thrust and 45mm-wide synchronous belt ensure 0.1mm-level pressing precision, resolving common issues like false pressing and misalignment in traditional slides, and enabling precision manufacturing of Mini LED and 5G modules. The integrated design of double-row linear sliders and thickened aluminum alloy base plates, combined with a 45mm-wide PM synchronous belt, ensures full-stroke deflection ≤0.1mm/m under 200KG loads, guaranteeing low-vibration high-speed operation. Featuring low-inertia servo motor direct-drive and high-tension synchronous belts, it achieves 97% transmission efficiency and a maximum speed of 2311mm/s (30% faster than conventional slides), tripling logistics sorting efficiency compared to traditional chain systems. With a flexible 50-4000mm stroke range: - Short strokes (50-500mm) suit precision tasks like dispensing and visual inspection.

- Long strokes (1000-4000mm) support cross-station handling in smart warehousing and automotive assembly.

Standardized interfaces enable rapid integration with multi-axis systems, reducing automation R&D cycles. Rooted in German Industry 4.0 principles, the PTB Slide balances speed, load, and precision through aerospace-grade materials, low-friction transmission, and anti-torsion structures. It is the ideal choice for upgrading automation lines in high-tempo logistics and micron-level electronics manufacturing.

| ※ Basic specifications |

|

| | Specification | Lead(mm) | 40 | | Max speed(mm/s) | 2000 | | Max speed (kg) | Horizontal | 25 | | Vertical | - | | Rated thrust (N) | 100 | | Standard stroke(mm) | 20-3050mm/50 interval | | Component | AC servo motor capacity | 200 | | Belt width | 25 | | High rigidity linear slider | W15×H12.5 | | Origin sensor Plug | PM-T45(NPN) | | (Unit:mm) (Unit:mm) |

| Horizontal

installation | A | B | C |

| Side

installation | A | B | C | | 10kg | 1794 | 688 | 538 |

| 15kg | 348 | 446 | 1170 | | 20kg | 858 | 324 | 253 |

| 18kg | 285 | 365 | 961 | | 25kg | 670 | 251 | 197 |

| 25kg | 197 | 251 | 670 |

| Motor folds left up |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| | Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | | L | 408 | 458 | 508 | 558 | 608 | 658 | 708 | 758 | 808 | 858 | 908 | 958 | 1008 | 1058 | 1108 | | A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | | M | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | | N | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | | KG | 8.2 | 8.6 | 9 | 9.5 | 10 | 10.5 | 11 | 11.4 | 12 | 12.4 | 13 | 13.4 | 13.9 | 14.4 | 14.9 | | Stroke | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 | 1400 | 1450 | 1500 |

| | L | 1158 | 1208 | 1258 | 1308 | 1358 | 1408 | 1458 | 1508 | 1558 | 1608 | 1658 | 1708 | 1758 | 1808 | 1858 |

| | A | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 |

| | M | 4 | 4 | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 8 |

| | N | 12 | 12 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 18 | 18 | 18 | 18 | 20 |

| | KG | 15.4 | 15.9 | 16.4 | 16.9 | 17.3 | 17.9 | 18.5 | 19.1 | 19.7 | 20.3 | 20.9 | 21.5 | 22.1 | 22.7 | 23.3 |

| | Stroke | 1600 | 1650 | 1700 | 1750 | 1800 | 1850 | 1900 | 1950 | 2000 | 2050 | 2100 | 2150 | 2200 | 2250 |

| | L | 1958 | 2008 | 2058 | 2108 | 2158 | 2208 | 2258 | 2308 | 2358 | 2408 | 2458 | 2508 | 2558 | 2608 |

| | A | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| | M | 8 | 8 | 9 | 9 | 9 | 9 | 10 | 10 | 10 | 10 | 11 | 11 | 11 | 11 |

| | N | 20 | 20 | 22 | 22 | 22 | 22 | 24 | 24 | 24 | 24 | 26 | 26 | 26 | 26 |

| | KG | 24.5 | 25.1 | 25.7 | 26.3 | 26.9 | 27.5 | 28.1 | 28.7 | 29.3 | 29.9 | 30.5 | 31.1 | 31.7 | 32.3 |

| | Stroke | 2300 | 2350 | 2400 | 2450 | 2500 | 2550 | 2600 | 2650 | 2700 | 2750 | 2800 | 2850 | 2900 | 2950 | 3000 | | L | 2658 | 2708 | 2758 | 2808 | 2858 | 2908 | 2958 | 3008 | 3058 | 3108 | 3158 | 3208 | 3258 | 3308 | 3358 | | A | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | | M | 12 | 12 | 12 | 12 | 13 | 13 | 13 | 13 | 14 | 14 | 14 | 14 | 15 | 15 | 15 | | N | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | 32 | 34 | 34 | 34 | | KG | 32.9 | 33.5 | 34.1 | 34.7 | 35.3 | 35.9 | 36.5 | 37.1 | 37.7 | 38.3 | 38.9 | 39.5 | 40.1 | 40.7 | 41.3 |

| Motor folds left (unite:mm) | | Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| | L | 408 | 458 | 508 | 558 | 608 | 658 | 708 | 758 | 808 | 858 | 908 | 958 | 1008 | 1058 | 1108 | 1158 |

| | A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 |

| | M | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 |

| | N | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 |

| | KG | 8.2 | 8.6 | 9 | 9.5 | 10 | 10.5 | 11 | 11.4 | 12 | 12.4 | 13 | 13.4 | 13.9 | 14.4 | 14.9 | 15.4 |

| | Stroke | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 | 1400 | 1450 | 1500 | 1550 | | L | 1208 | 1258 | 1308 | 1358 | 1408 | 1458 | 1508 | 1558 | 1608 | 1658 | 1708 | 1758 | 1808 | 1858 | 1908 | | A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | | M | 4 | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 8 | 8 | | N | 12 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 18 | 18 | 18 | 18 | 20 | 20 | | KG | 15.9 | 16.4 | 16.9 | 17.3 | 17.9 | 18.5 | 19.1 | 19.7 | 20.3 | 20.9 | 21.5 | 22.1 | 22.7 | 23.3 | 23.9 | | Stroke | 1600 | 1650 | 1700 | 1750 | 1800 | 1850 | 1900 | 1950 | 2000 | 2050 | 2100 | 2150 | 2200 | 2250 | 2300 | 2350 | | L | 1958 | 2008 | 2058 | 2108 | 2158 | 2208 | 2258 | 2308 | 2358 | 2408 | 2458 | 2508 | 2558 | 2608 | 2658 | 2708 | | A | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | | M | 8 | 8 | 9 | 9 | 9 | 9 | 10 | 10 | 10 | 10 | 11 | 11 | 11 | 11 | 12 | 12 | | N | 20 | 20 | 22 | 22 | 22 | 22 | 24 | 24 | 24 | 24 | 26 | 26 | 26 | 26 | 28 | 28 | | KG | 24.5 | 25.1 | 25.7 | 26.3 | 26.9 | 27.5 | 28.1 | 28.7 | 29.3 | 29.9 | 30.5 | 31.1 | 31.7 | 32.3 | 32.9 | 33.5 | | Stroke | 2400 | 2450 | 2500 | 2550 | 2600 | 2650 | 2700 | 2750 | 2800 | 2850 | 2900 | 2950 | 3000 | 3050 |

| | L | 2758 | 2808 | 2858 | 2908 | 2958 | 3008 | 3058 | 3108 | 3158 | 3208 | 3258 | 3308 | 3358 | 3408 |

| | A | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| | M | 12 | 12 | 13 | 13 | 13 | 13 | 14 | 14 | 14 | 14 | 15 | 15 | 15 | 15 |

| | N | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | 32 | 34 | 34 | 34 | 34 |

| | KG | 34.1 | 34.7 | 35.3 | 35.9 | 36.5 | 37.1 | 37.7 | 38.3 | 38.9 | 39.5 | 40.1 | 40.7 | 41.3 | 419 |

|

|