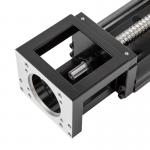

CNC Specific Linear Slide High Precision High Load Capacity

SEXGL Linear Slide deliver unparalleled accuracy and

durability in high-precision automation systems, trusted by global

leaders like BYD (EV powertrain assembly) and BOE (LCD panel

cutting robots) across North America, Europe, Southeast Asia, and

South Korea.In CNC machining, precision, efficiency, and stability

are key. Our linear slides, tailored for CNC, enable precise

positioning and efficient motion—core to reliable linear solutions

for all CNC equipment, enhancing quality and productivity.

Key Features

1.High-Precision PositioningUses advanced ball screws/linear guides with precision

manufacturing, achieving ±0.01mm positioning and ±0.005mm

repeatability for micron-level accuracy.

2.Wide Load CapacityModels support 50–500kg, handling cutting/impact loads in

small-part machining to heavy-duty workpiece processing, ensuring

stable equipment support.

3.High-Rigidity StructureBuilt from high-strength aluminum/steel with reinforced designs

(ribs/symmetry), resisting deformation under high-speed/heavy loads

to maintain motion stability and extend equipment life.

4.High-Speed PerformancePaired with servo/stepper motors, reaches 1000mm/s max speed,

reducing idle time for faster batch processing and higher CNC

productivity.

5.Low Noise & LongevityPrecision components + smart lubrication keep noise <60dB.

Premium materials/surface treatments (hard chrome/anodizing)

minimize wear, lowering maintenance costs over 20k+ hours.

| ※ Basic specifications |

|

|

|

|

|

| Specification | Standard motor power (W) | 200W |

| Repeatable positioning accuracy(mm) | ±0.01 |

| Screw specification | 1605 | 1610 | 1616 | 1620 |

| Max speed (mm/s) | 250 | 500 | 800 | 1000 |

| Rated thrust (N) | 683 | 341 | 213 | 174 |

| Max load (kg) | Horizontal | 50 | 30 | 22 | 18 |

| Vertical | 12 | 8 | 5 | 3 |

| Max stroke (mm) | 1050 |

| Component | Screw specification | 1605/1610/1616/1620(Slenderness ratio1:62.5) |

| Screw grade | C7 rolling |

| High rigidity linear slider | W20×H18 |

| Coupling | 34-27-10-14 |

| Photoelectric switch | PM-T45(NPN) |

| (Unit:mm) (Unit:mm) |

|

|

|

| (Unit :mm) (Unit:N.m) |

|

|

|

|

| |

Horizontal

installation | A | B | C | Side

installation | A | B | C | Vertical

installation | A | C | MY | 110 |

| MP | 110 |

| Lead 05 | 30kg | 547 | 42 | 42 | Lead 05 | 25kg | 52 | 53 | 670 | Lead 05 | 5kg | 310 | 310 | MR | 120 |

| 40kg | 391 | 29 | 29 | 35kg | 35 | 45 | 455 | 8kg | 192 | 192 |

|

|

| 50kg | 298 | 22 | 22 | 50kg | 21 | 22 | 298 | 12kg | 129 | 129 |

|

|

| Lead 10 | 15kg | 521 | 84 | 80 | Lead 10 | 10kg | 124 | 131 | 770 | Lead 10 | 4kg | 335 | 335 |

|

|

| 25kg | 298 | 47 | 44 | 20kg | 58 | 61 | 382 | 6kg | 220 | 220 |

|

|

| 30kg | 242 | 34 | 35 | 30kg | 35 | 37 | 242 | 8kg | 172 | 172 |

|

|

| Lead 16 | 5kg | 937 | 282 | 259 | Lead 16 | 5kg | 116 | 58 | 605 | Lead 16 | 1kg | 620 | 620 |

|

|

| 10kg | 487 | 121 | 116 | 10kg | 24 | 26 | 253 | 2kg | 680 | 680 |

|

|

| 22kg | 236 | 40 | 44 | 22kg | 0 | 0 | 0 | 5kg | 310 | 310 |

|

|

| Lead 20 | 5kg | 675 | 224 | 193 | Lead 20 | 6kg | 160 | 185 | 562 | Lead 20 | 1kg | 580 | 580 |

|

|

| 10kg | 330 | 107 | 93 | 12kg | 76 | 88 | 272 | 2kg | 645 | 645 |

|

|

| 18kg | 175 | 55 | 48 | 18kg | 48 | 55 | 175 | 3kg | 310 | 310 |

|

|

Motor exposure-01

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Unit:mm |

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| L | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 |

| A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 |

| M | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 |

| N | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 |

| KG | 5.5 | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 |

Motor exposure-02

| Unit:mm |

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| L | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 |

| A | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| M | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 |

| N | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 14 |

| KG | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 | 13.2 |

Motor folds right-01

| Note:The left fold of the motor is symmetrical with this figure Unit:mm |

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| L | 329.5 | 379.5 | 429.5 | 479.5 | 529.5 | 579.5 | 629.5 | 679.5 | 729.5 | 779.5 | 829.5 | 879.5 | 929.5 | 979.5 | 1029.5 | 1079.5 | 1129.5 | 1179.5 | 1229.5 | 1279.5 |

| A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 |

| M | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 |

| N | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 |

| KG | 5.5 | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 |

Motor folds right-02

| Note:The left fold of the motor is symmetrical with this figure Unit:mm |

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

|

| L | 379.5 | 429.5 | 479.5 | 529.5 | 579.5 | 629.5 | 679.5 | 729.5 | 779.5 | 829.5 | 879.5 | 929.5 | 979.5 | 1029.5 | 1079.5 | 1129.5 | 1179.5 | 1229.5 | 1279.5 | 1329.5 |

|

| A | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

|

| M | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 |

|

| N | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 14 |

|

| KG | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 | 13.2 |

|