The preform visual inspection machine generates comprehensive

defect output software packages, providing visibility into quality

issues for informed decision-making. Ensure the highest quality

standards with our state-of-the-art visual inspection solution.

Elevate your quality control with our preform visual inspection

machine, expertly designed for the appearance defect of PET

preforms. Featuring a proprietary high-definition camera (“HD Eye”)

and advanced optical imaging, this machine captures clear images

for precise defect detection. Powered by our robust AI cloud

platform (“Super Brain”), it processes, analyzes, and labels images

swiftly, establishing accurate defect models.

- The Latest advanced AI algorithm KVIS-V16.0

- Modularization embedded processing unit

- Surging computing power NPU chip

- Cloud platform for remote operation&maintenance

- Self-developed hardware and software system

- High compatibility with various product kinds

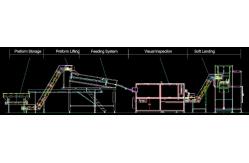

Fully Automatic Preform Visual Inspection Machine Production Line

The preform visual inspection machine is the most important part in

quality control of preforms. In a modern preform detection

production line, it needs to include automatic dumper, preform

storage system, lifting machine, embryo feeding machine, visual

inspection machine, and conveyor line. Each preform manufacturer

can choose personalized equipment configuration according to

automation requirements, but visual inspection as the core machine

is a must. The following is an introduction to our company’s latest

preform inspection system.

Inspection Theory

8 camera preform visual inspection machine is a fully automatic

equipment for product appearance defect detection, which adopt the

latest KVIS-V16.0 AI vision system, the inspected product is stably

and orderly transmitted to a specific workstation through a

material handling (feeding) device, and the high pixel sample

images captured are transmitted to image processing software

through customized Led light sources and industrial cameras.

AI inspection system is analyzed and compared, and the system

automatically determines “NG” and “OK” products. The corresponding

pneumatic components are controlled to reject the defective

products online, and the good products are counted and packaged

directly, or transferred to the next production stage.

The software will open up sample comparison standards, and

production personnel at the customer’s site can control the

comparison accuracy, select the most suitable accuracy standard for

their own production situation, and thus control the defect rate.

Main characters

- The Latest advanced AI algorithm

- Modularization embedded processing unit

- Surging computing power NPU chip

- Cloud platform for remote operation&maintenance

- Self-developed hardware and software system

- High compatibility with various product kinds