Lab Equipment IEC60695 Hot Wire Ignition Tester , HWI Test

Equipment Product information: This tester conforms to the standard requirement of IEC60695-2-20.

It is suitable for electric and electronic products, household

appliance materials to do ignition dangerous test. It simulates the

heat source or ignition source of simulates glow component and

overload resistance which may cause thermal stress in a short time. Hot-wire coil ignition test adopts the specific size(ф0.5mm

length:250mm)and specific material (Ni80/Cr20) of heater strip

which is pre-annealed with required heating power(0.26W/mm) and

time(8s~12s). Then coil heater strip on the specimen for 5 cycles

according to certain wire wrapping tension (5.4N) and certain wire

wrapping distance (6.35mm). Next, take the specimen with wrapping

heater strip to test until 120s under the stipulate heating power

(0.26W/mm) the users can judge the fire risk according to whether

the specimen ignite and the ignite time. Technical parameters: Parameter model | HWI-1 | conforms to standard | IEC60695-2-20,GB4943 | Heating coil | ф0.5mm,Ni80/Cr20,length:250mm±5mm ,cold resistance 5.28Ω/m | Anneal holder distance | 250mm | Specimen holder distance and height | 70mm,high:60mm(the distance between the holder surface to the

connector plate surface) | Wire wrapping tension and its distance | 5.4N±0.05N,6.3mm±0.2mm(within 31.5mm±0.5mm,coil 5 cycle,national

standard is 6mm) | Annealing time and power | 8s~12s(1s~999.9s digital display can be preset),0.26W/mm±4%(digital

display is adjustable) | Testing time and power | 120s(1s~999.9s digital display can be preset),0.26W/mm±4%( digital

display is adjustable) | Specimen size | L×W×H:(125 ± 5mm) ×(13.0 ± 0.5mm) ×(0.75+0.075

0mm,1.5+0.15 0mm,3+0.3 0mm)[ national standard is 0.75±

0.1 mm,1.5± 0.1 mm,3± 0.2 mm] | Combustion box volume | Greater than0.5 cube(can be order 0.75 cube,1cube) | Power supply | AC 220V±10%,50Hz;110V,60Hz |

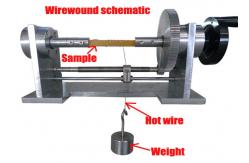

Hot Wire Ignition Test is a type of resistance test to fire for

materials of enclosures and decorative parts. The sample is put on

a specified stand and an element wire is winded around the material

to be tested

Technical specification

The test sample is sourced by DC power

Element Wire 80% Nickel and 20% Chromium – 3 bobbins included

Power consumption 0.26 W/mm – means a current of 7 A to passes

through the element wire

Digital Ammeter and Voltmeter

Terminal to connect the element wire |