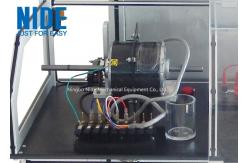

Coil Winding Stator Servo Motor Test Equipment

|

|

Electric motor testing equipment, DC motor test and monitoring bench for everything around winding and motor

This intelligent electric motor testing equipment is suitable for testing motors of different specifications; it is convenient to move and change test molds, and it adopts a combination of touch screen and buttons to facilitate personnel operation; it has self-diagnosis and remote automatic upgrade functions to facilitate later system upgrade and maintenance

I. Application industries: The motor testing machine is suitable for household appliance motors, fan motors, water pump motors, stepper motors, servo motors.

II. Introduction 1. Test station: double test station 2. Test items: AC Hipot:winding to iron core; Insulation resistance:winding to iron core; Surge:winding to winding; Winding resistance:winding to winding; No-load test: no-load electrical parameters; Low-start test: low-voltage starting electrical parameters Stall test: simulation of stall parameters; Direction of rotation:The actual turning of the motor;

III. System Features 1. Linux operating system, professional control software, simple interface 2. Standard equipped with code scanning function (optional equipped with code scanner) 3. Standard equipped with yellow, green and red indicating light. Yellow-in test, green-pass, and red-fail. 4. Temperature compensation: automatically converted the tested value to that under standard temperature. 5. The test time for one stator is less than 8s. 6. The left station and right station can work separately to improve the testing efficiency. 7. The light and sound alarm will be triggered in case of any equipment failure or the stator fails the test. 8. The color of the testing system is aluminum primary color. 9. Multiple interfaces: USB, LAN, CAN, RS232. 10. Support to connect with the MES system (production management system).

IV. Technical Parameters 1. AC Hipot:Applied AC high voltage from the silicon steel sheet to iron core, and test the current of testing loop.

2. Insulation resistance:apply DC high voltage between winding and iron core and check the insulation resistance of testing loop.

3. Surge:apply impulse high voltage to windings, and compare the oscillation graph with the saved graph.

4. DC winding resistance:four-wire resistance measuring method. Apply DC current to the windings and test the temperature and winding resistance under current environment. The resistance will be converted to the value under designated temperature(generally 20℃ or 25℃) automatically.

5. No-load / low-voltage start / stall test:

6. Direction of rotation:the rotation is tested by monitoring the change of magnetic field Rotation: CW, CCW and still

V. Picture show

|

||||||||||||||||||||||||||||||||||||||||

| Product Tags: automatic test equipment electric motor test equipment |

|

Automatic BLDC Wheel Hub Motor Testing Machine |

|

Double Test Station Coil Winding Stator Testing Machine For induction electric motor |

|

Coil Winding Stator Servo Motor Test Equipment |

|

DC Motor Two Stations Armature Testing Machine |

|

Air Conditioner BLDC Motor Testing Equipment |

|

0.5KW Power Motor Testing Equipment Small Size With Double Station |