CHENLIFT (SUZHOU) MACHINERY CO LTD

|

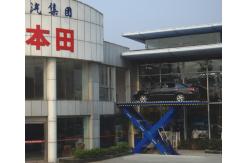

Chenlift (Suzhou) Machinery Co Ltd is one of the leading aerial work platform and logistic loading and unloading machines manufacturer in Suzhou, China. With the brand name of Bestmax Lift

Chen Lift have been served our customers with the design, manufacturing, and installation of aerial work platform and logistic loading and unloading machines for more than fifteen years. Our machines have enjoyed great popularity among our domestic and foreign customers in over 50 countries.

Our goal is to help our customers achive success by solving problems, increasing working effiency and lowering management cost. We give top priority to quality of products by continuous innovation and shoulder the responsibility to provide customers with safe and efficient products.

Excellent working team, clear cut development direction, good after sale service, advanced manufacturing equipment, and restrict safety requirements, all theses are the prerequisites for us to provide our customer with satisfying machines.

Machines also can be manufactured based on our customers' requirments, our team will take good care of our customer's needs and try our best to reach their expectation.

Chen Lift take "Focus, Innovation, Dedication, Sincerity, Care, Earnest" as our valued priciple.

Warmly welcome to visit our factory and we are looking forward to cooperating with you for mutual benefits.

|

- Basic Information

-

Company Name: CHENLIFT (SUZHOU) MACHINERY CO LTD Business Type: Manufacturer Brands: CHEN LIFT Employee Number: 50~100 Factory Location: Add: E-3 Building No 28 Yongchang Road Xiangcheng District Suzhou Jiangsu China - Trade & Market

-

OEM Overview: We have more than 11000 quare meters factory to produce nearly 90% accessories by ourselves , not only save cost but also can contrl quality very well , we have manager of each necessary process , regular quality test ,the cord is together with their salary , this year we will have some better and new rules on quality and quantity , please set your heart at rest to do business with us .

Production Line: Full Set of Painting Line

We have a full set of spray equipment line wich can spray the parts with paint uniformly and make the color of the parts vividly. Because of this painting line, the paint of the machine will not be damaged easily.

Blasting Machine

Using the blasting machine to derust the profile can clear the rust clearly. After machine derusting our workers will use the derusting tools to remove the rust that hidding in ther corner. These derusting procedures will add the adhesiveness between the profile and paint.

Arc Welding Machine

In order to save the cost, most factories do not equipped with the Arc Welding Machine. Their workers are using welding torch which may cause the uneveness of the welding seam. As the machine can weld without stopping, the temperature is set, the welding beam is flat and even.

About quality management: Quality Control

Global Supply Chain-Materials & Components

The key components of the machine are imported to ensure the best quality, such as the electric distribution is from Schneider in France and the motor is from Bucher in Swiss. And all the alloy and steel materials and other main components are also first-class products in China.

Q/C Technical Support

Our Company has a R&D team of more than 30 engineers. In addition, because of our collaboration with top engineering universites in China, we are able to add additional engineering support in our never-ending quest to provide our customers with the finest technology available.

Strict quality control system has been implemented in each production procedure: imported key components are used to ensure high quality; advanced equipment is used for examining and control quality; every product is carefully tested before shipment; and all the quality complaints and improvement suggestions will be seriously studied, if reasonable, put into practice immediately. We have comprehensive monitoring system for the construction design process. In such way, we can not only control our costs, but also ensure the high quality of our products.

Production Process and Examination Details

The quality control is strictly in accordance with ISO9001 quality management system and CE requirement. When the products are finished, the inspection is 100% executed strictly

- Strict quality control system on the whole process of production

- Imported key arts to ensure the high quality of our products

- Advanced equipment and tools for examination and quality control

- 100% strict examining products before shipment

- All the quality complaints and improvement requirements are always be studied seriously, if reasonable, put into practice immediately.

Services: Our Team: We have professional mechanical engineers with many years relevant working experience especially in the aerial working platform field.

Qualified welding, assembling, painting and manufacturing workers.

Competent sales men who can provide you good sale and after sale services.

Financial Department and HR deparment.

- Factory Information

-

Market name: North America,South America,Western Europe,Eastern Europe,Eastern Asia,Southeast Asia,Middle East,Africa,Oceania,Worldwide Contact Person: Mr.Aijun Liu Contact Phone: 86--13951119762