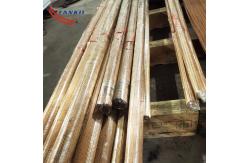

Manufacture Supply C17300 C17510 C17150 Beryllium Copper Rod /

C17200 Becu Beryllium Copper Round Bar Price Per Kg UNS C17300 beryllium copper alloys are heat treatable, ductile and

can be mill hardened. They offer tensile strength of 1380 MPa (200

ksi). These steels are suitable for applications requiring good

conductivity, high strength and stiffness. This article will give an overview of UNS C17300 beryllium copper

alloys. Chemical Composition The following table shows the chemical composition of UNS C17300

copper. | Element | Content (%) |

|---|

| Cu | 97.7 | | Be | 1.9 | | Co | 0.40 |

Physical PropertiesThe physical properties of UNS C17300 copper are given in the

following table. | Properties | Metric | Imperial |

|---|

| Density (during age hardening, 2% max. decrease in length and 6%

max. increase in density) | 8.25 g/cm3 | 0.298 lb/in3 | | Melting point | 866°C | 1590°F |

Mechanical PropertiesThe mechanical properties of UNS C17300 copper are tabulated below. | Properties | Metric | Imperial |

|---|

| Hardness, Rockwell B | 80.0 - 85.0 | 80.0 - 85.0 | | Tensile strength, ultimate | 515 - 585 MPa | 74700 - 84800 psi | | Tensile strength, yield | 275 - 345 MPa | 39900 - 50000 psi | | Elongation at break | 15.0 - 30.0% | 15.0 - 30.0% | | Modulus of elasticity | 125 - 130 GPa | 18100 - 18900 ksi | | Poissons ratio | 0.300 | 0.300 | | Machinability (UNS C36000 (free-cutting brass) = 100%) | 20% | 20% | | Shear modulus | 50.0 GPa | 7250 ksi |

Beryllium copper rods find applications in various industries and

sectors due to their unique properties. Here are some common

applications of beryllium copper rods:

Electrical connectors and switches: Beryllium copper rods are

widely used in electrical connectors and switches due to their

excellent conductivity and mechanical strength. They provide a

reliable electrical connection while withstanding repeated mating

and unmating cycles. Springs and contacts: Beryllium copper rods are commonly used in

spring applications where high strength, durability, and good

elasticity are required. They are used in springs for various

industries, including automotive, aerospace, electronics, and

telecommunications. Beryllium copper contacts are also used in

electrical connectors and switches to ensure efficient electrical

transmission. Welding and resistance welding electrodes: Beryllium copper rods

are used as welding electrodes due to their high thermal

conductivity, heat resistance, and resistance to welding spatter.

They are commonly employed in resistance welding applications where

precise and consistent welding is required. Bearings and bushings: Beryllium copper rods are utilized in the

manufacture of bearings and bushings due to their excellent wear

resistance, low friction, and high strength. They provide reliable

performance and extended service life in demanding applications,

such as automotive, aerospace, and industrial machinery. Tooling and molds: Beryllium copper rods are used in tooling and

mold applications that require high strength, dimensional

stability, and resistance to wear and corrosion. They are employed

in injection molds, blow molds, and die-casting molds to achieve

precise and durable tooling. Oil and gas industry: Beryllium copper rods find applications in

the oil and gas industry, particularly in downhole tooling, where

high strength, corrosion resistance, and reliability are crucial.

They are used in components such as drill collars, drill bits, and

valves. Aerospace and defense applications: Beryllium copper rods are

utilized in various aerospace and defense applications due to their

high strength, durability, and resistance to fatigue. They are

employed in components such as connectors, springs, contact

springs, and electrical contacts. -

|