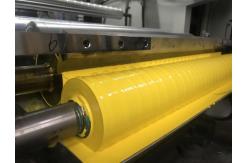

PRY4-1000 Four Colors Flexo Printing Machine

|

Detailed Product Description

|

PRY4-1000 Four Colors Flexo Printing Machine Features This machine is a printing machine using a photosensitive resin

soft plate as a plate material,commonly known as "aniline printing

machine","flexographic printing machine", "embossing printing

machine","flexo printing machine".Suitable for printing

polyethylene, polypropylene,cellophane,plastic film(BOPP OPP PE PVC

PET,etc.),non-woven fabric, woven bag,paper and other packaging

materials,is food packaging,supermarket handbags,vest bags,clothing

bags and other flexible packaging Ideal printing equipment. Performance and Features: Assembly of 75mm thick cast iron machine plate. 1.Simple operation, accurate color registration and long service life. 2.Adopt motor,frequency conversion speed regulation,save electricity,small fluctuation of operation. 3.The printing plate automatically stops the ink motor,and the printing device automatically starts the ink discharging device. 4.Adopt special timing belt drive,the printing size is accurate. 5.There is a hair dryer,in which the heating uses a central constant temperature control system and is controlled in groups. 6.The low roll is processed with special steel and processed by special process and electroplated with 10 wire thick hard chrome protective layer. 7.Aluminum alloy guide wheel for hard oxidation,dynamic balance,static balance treatment. 8.With cold air shaping bellows,it can effectively prevent defects such as ink sticking after printing. 9.The printed image is clear and the layering is strong. Technical Parameters

Configuration 1.The fuselage adopts 75mm thick wall panel,increase the balance

bar and other enhanced machine stability. 2.The printing stick adopts an enlarged thick steel bar and is

plated with a 10 wire thick hard chrome protective layer for

polishing.The aluminum alloy guide wheel is subjected to hard

oxidation,dynamic balance and static balance treatment. 3.High-precision widening synchronous belt drive,low noise when the

machine runs at high speed,low vibration makes the machine more

stable,the plate roller gear is driven by special helical gear,the

printing length of each tooth is 5mm,the printing effect is more

stable,the printing length is more precise. 4.Printing unit 5.Unwind/rewind 6.Heating unit |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

PRY4-1000 Four Colors Flexo Printing Machine |

|

PRY-D1224 High Speed Full Automatic 4 Color Flexo Printing Slotting Die Cutting Stacking Machine |

|

PRY-B400 Semi Automatic 2 Colors Flexo Printing Slotting Die Cutting Machine |

|

PRY-D400 Automatic Lead Edge 4 Colors Flexo Printing Slotting Die Cutting Machine with Stacker |

|

ZYT-1000-4 Stackable Paper Bag Four Colors Flexo Printing Machine |

|

PRY-1000-6 Unit Type Paper Cup Six Color Flexo Printing Machine |

Email to this supplier