Brilliant Rays Wheels Trading Co.,Limited

|

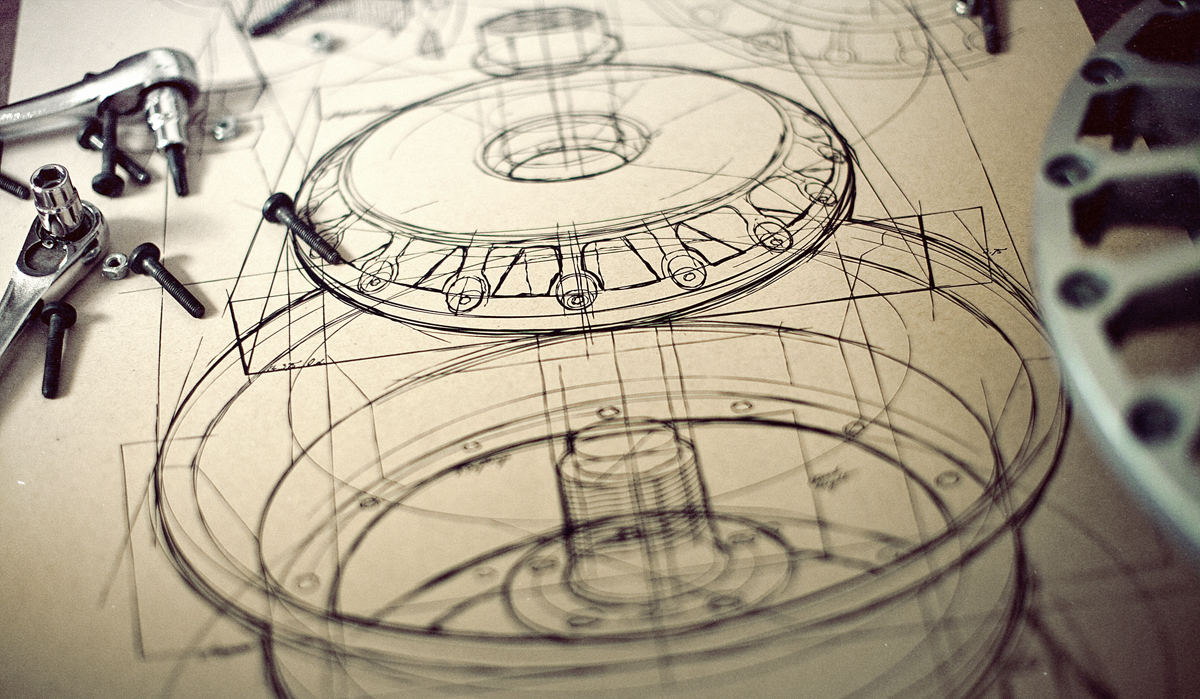

As a professional wheel provider. We provide payment terms such as Paypal, Western Union, Bank Remittance and etc. We provide Cargo insurance and Customs Clearance services. Air Parcel, Surface Air Lift and Surface Parcel are available for the transportation. The price here is perfectly competitive. As for professional design ability, we have good wheel design, innovation,drawing (2D, 3D) , wheel finite element analysis; Full control of manufacturing process,and onine order integration.

Brilliant Rays Wheels Trading Co., Limited was set up in 2013 by

Steven and his friends.

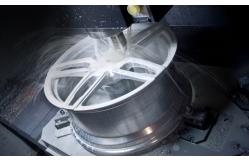

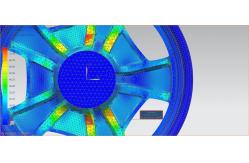

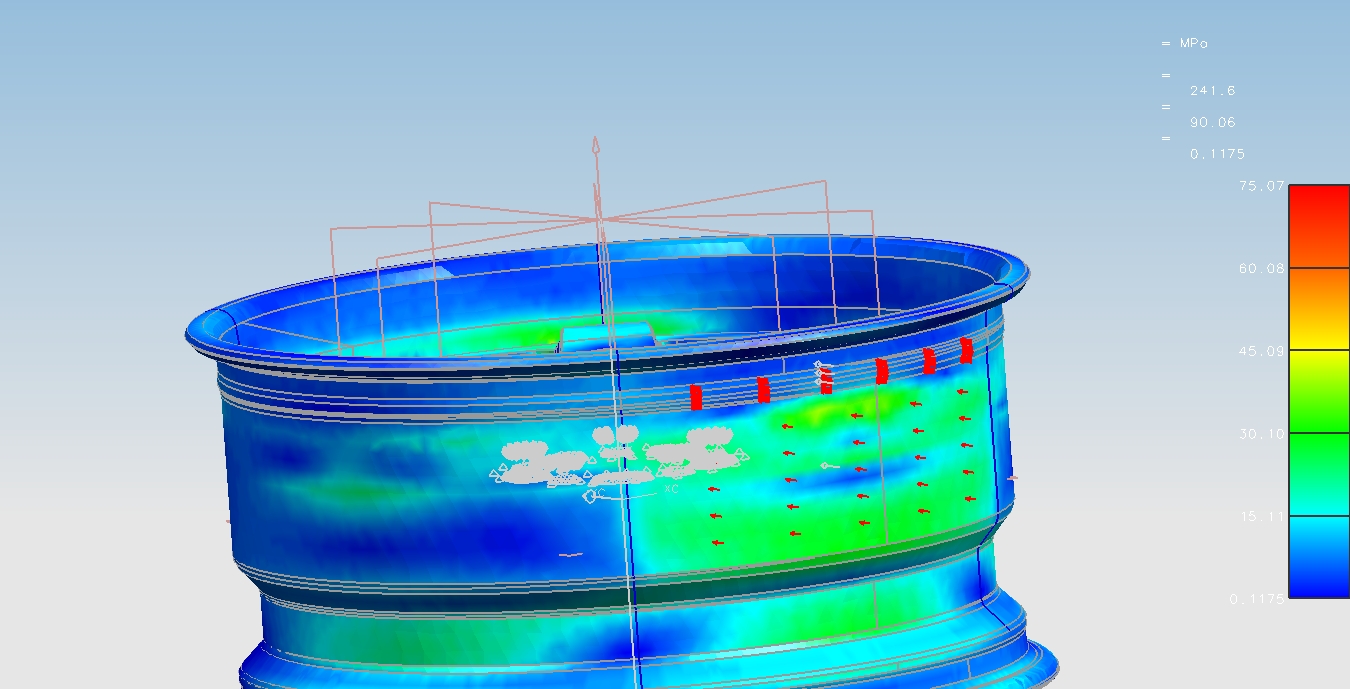

Technology The rotary forging process has significant advantages over conventional forging. Rotory forging produces a very tight grain structure. When combined with spinning this state-of-the-art technology results in substantial benefits in the internal structure of heavy duty aluminum wheels. It is a CCIF (Computer Controlled Incremental Forming) process used to progressively form the material into the shape desired. This rotary forging process orientates and aligns the aluminum grain structure in a radial pattern for maximum strength. Material incremental deformation is achieved by combined rotational movement and axial compression. Greater surface finish quality (no cracks as a result of impact as in closed forging) as the material flow is incremental. Material hardening and optimized grain structure More uniform mechanical properties. Computer Controlled Spinning Technology, which is a metalworking process utilizing a mandrel and multiple rollers to efficiently produce near net shape axis symmetric parts in moderate to high volume. It is a Precision CCFF (Computer Controlled Flow Forming) process where rollers form the material against the mandrels to produce the rim profile. This enables us to achieve the distinctive material properties with uniform grain flow and surface finish in the rim area.

|

- Basic Information

-

Company Name: Brilliant Rays Wheels Trading Co.,Limited Business Type: Manufacturer,Agent,Exporter,Trading Company,Seller Brands: Brilliant Rays Employee Number: 150~200 Factory Location: Building 20, No. 6055 Jinhai Road, Fengxian District, Shanghai, China - Trade & Market

- Factory Information

-

Market name: North America,South America,Western Europe,Eastern Europe,Eastern Asia,Southeast Asia,Middle East,Oceania,Worldwide Contact Person: Mr.Danny Contact Phone: +86-132-58156783