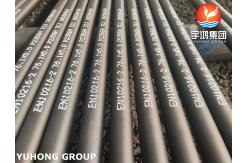

EN10216-2 P235GH TC1 Heat Exchanger Tube For High Temperature Environments

|

|

Yuhong Group has more than 35 years experience for project package , till now finished more than 2000 projects , and export more than 85 countries , Yuhong Brand already won good reputation in the world, 85% orders from client re-peat order.

Yuhong Group advantage products- Shell and Tube Heat Exchanger , the material cover : Stainless Steel, Duplex Steel , Super Duplex Steel , Nickel Alloy , Alloy Steel , Copper and Copper Alloy, Titanium , Carbon Steel , Overlay cladding & Explosion cladding.

We can support design:Thermal Calculation (HTRI) , Mechanical Calculation (PV Elite), GA drawing and detail drawings , all procedure control documents (JIC , PQR, WPS, WPQ, NDT,......), All of our heat exchangers according to TEMA standard and can apply ASME U Stamp , we also can make heat exchangers according to client design .

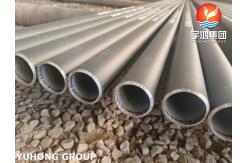

EN10216-2 P235GH TC1 Heat Exchanger Tube for High Temperature Environments

EN10216-2 P235GH TC1 Heat Exchanger Tube refers to a seamless steel tube designed for pressure

applications. As the European standard for seamless steel tube for pressure purposes, it covers the technical delivery conditions for steel tube used in boilers, heat exchangers and piping systems. P235GH tube has a minimum specified yield strength of 235 MPa at room temperature and is suitable for high temperature gas environments

TC1: Basic testing requirements.

Testing content includes:

Hydrostatic or ultrasonic testing. One tensile test per batch. One flattening/bending test per batch.

Note: TC2 requires more stringent testing (e.g., comprehensive non-destructive testing, more frequent testing)

EN 10216-2 Grade P235GH Heat Exchanger Tube Chemical Properties

EN 10216-2 Grade P235GH Heat Exchanger Tube Mechanical Properties

EN 10216-2 Grade P235GH Heat Exchanger Tube Equivalent Designation

Application

Steam Boilers: Water walls, economizers and low pressure steam piping

Heat Exchangers: Condensers, feedwater heaters and cooling system tubes.

District Heating Systems: Hot Water Pipes

Process Piping for Non-Corrosive Fluids.

Structural Support for Pressure Vessels

Thermal Fluid Systems (Thermal Oil Loops).

High Strength Piping for Heating/Cooling Systems.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: TC1 P235GH Heat Exchanger Tube EN10216-2 P235GH Heat Exchanger Tube | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

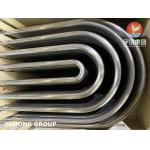

ASTM A213 TP304L Austenitic Stainless Steel Seamless U Bend Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

U Bending ASTM A213 TP304L Stainless Steel For Boiler and Heat Exchanger |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |