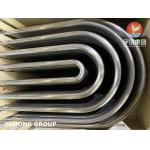

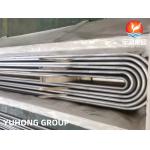

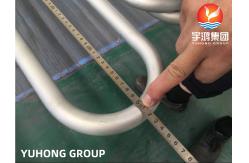

U Bending ASTM A213 TP304L Stainless Steel For Boiler and Heat

Exchanger

YUHONG GROUP deal with stainless steel seamless pipe and tube already more than

33 years, every year sell more than 80000 tons of stainless steel

seamless pipe and tube. Our client already cover more than 65

countries. Our stainless steel seamless pipe and tube was width

used in Mining, Energy, Petrochemical, Chemical Industry, Food

plant, Paper plant, Gas and Fluid Industry etc.

Description

Grade304 is the standard "18/8" stainless; it is the most versatile

and most widely used stainless steel, available in a wider range of

products, forms and finishes than any other. It has excellent

forming and welding characteristics. The balanced austenitic

structure of Grade 304 enables it to be severely deep drawn without

intermediate annealing, which has made this grade dominant in the

manufacture of drawn stainless parts such as sinks, hollow-ware and

saucepans. for these applications it is common to use special

"304DDQ" (Deep Drawing Quality) variants. Grade 304 is readily

brake or roll formed into a variety of components for applications

in the industrial, architectural, and transportation fields. Grade

304 also has outstanding welding characteristics. Post-weld

annealing is not required when welding thin sections.

In fact, according to the content of chromium and nickel, all of

them are 304 stainless steel, with 18% chromium (CR) and 8% nickel

(Ni), but the main difference lies in the carbon content.

Among them, the highest carbon content is 304H, the lowest is 304L,

and the carbon content of 304 stainless steel is between the two.

The higher the carbon content, the worse the corrosion resistance

of stainless steel. Different carbon content also leads to

different prices. However, in actual use, different requirements

for different uses are different.

Grade304L, the low carbon version of 304, does not require

post-weld annealing and so is extensively used in heavy gauge

components (over about 6mm).Grade304H with its higher carbon

content finds application at elevated temperatures. The austenitic

structure also gives these grades excellent toughness, even down to

cryogenic temperatures.

Chemical composition

America standard | European standard | C % max | Mn % max | P % max | S % max | Si % max | Cr % | Ni % | Mo% |

TP304 | 1.4301 | 0.080 | 2.0 | 0.045 | 0.03 | 1.00 | 18.00-20.00 | 8.00-11.00 | - |

TP304L | 1.4307 | 0.035 | 2.0 | 0.045 | 0.03 | 1.00 | 18.00-20.00 | 8.00-12.00 | - |

TP304H | / | 0.04-0.10 | 2.0 | 0.045 | 0.03 | 1.00 | 18.00-20.00 | 8.00-11.00 | - |

Mechanical properties

– | Tensile Strength | Yield Strength | Elongation | Hardness | Hardness |

Grade | (MPa) min | 0.2% Proof (MPa) min | (% in 50mm) min | Rockwell B (HR B) max | Brinell (HB) max |

304 | 515 | 205 | 35 | 90 | 192 |

304L | 485 | 170 | 35 | 90 | 192 |

304H | 515 | 205 | 35 | 90 | 192 |

Grade specifications for 304L grade stainless steel

Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS |

BS | En | No | Name |

304 | S30400 | 304S31 | 58E | 1.4301 | X5CrNi18-10 | 2332 | SUS 304 |

304L | S30403 | 304S11 | - | 1.4306 | X2CrNi19-11 | 2352 | SUS 304L |

304H | S30409 | 304S51 | - | 1.4948 | X6CrNi18-11 | - | - |

These comparisons are approximate only. The list is intended as a

comparison of functionally similar materials not as a schedule of

contractual equivalents. If exact equivalents are needed original

specifications must be consulted. |

Application