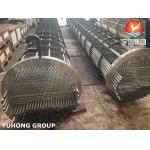

Shell And Tube Heat Exchanger ASME Section Viii Division 1 U Stamp Certificated

|

Detailed Product Description

|

Shell And Tube Heat Exchanger ASME Section Viii Division 1 U Stamp Certificated

SS31803 Tubes & SA-106 Grade B Shell Material Construction

ASME Section VIII Division 1 Compliance

Customizable Design

Performance Specifications

Technical Specifications Table

|

|||||||||||||||||||||

| Product Tags: SS31803 Tubes Shell Tube Heat Exchanger SA-106 Heat Exchanger Tube Bundle SS31803 Heat Exchanger Tube Bundle |

Related Products

|

ASME U Stamp Customized Heat Exchanger Steel Tube Bundle For Oil Refining |

|

Heat Exchanger Tube Bundle D-E1 A ASME SA213 T11 U Bend Tube With ASME SA-516 GR.70 (N, FGP) Tubesheet ASME U STAMP |

|

Tube Bundle ASME U STAMP D-E05C ASME SA179 Carbon Steel Seamless Tube With ASME SA266 Gr.2N Tubesheet |

|

ASME U Stamp Customized Tube Bundle Steel Heat Exchanger Seamless Tube |

|

U Bend Tube Bundle , Stainless Steel U Tube Type Fuel Oil Heater |

|

Stainless Steel / Carbon Steel / Copper Alloy Tube Bundle For Shell And Tube Heat Exchanger |

Email to this supplier