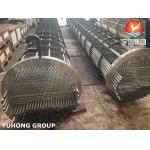

ASME U Stamp Customized Heat Exchanger Steel Tube Bundle For Oil Refining

|

|

Customized Oil-Cooled Heat Exchanger Stainless Steel Tube Bundle

Oil heat exchanger is a device that transfers thermal energy between two or more fluids, specifically using oil as one of the fluids. It usually has three types: 1>. Shell and Tube: Comprising a series of tubes, where one fluid flows through the tubes while the other flows outside them. 2>. Plate: Made up of thin plates stacked together, allowing for compact design and efficient heat transfer. 3>. Air-cooled: Uses air to cool or heat oil, typically used in applications where water is scarce.

Common use material for Tube Bundle Heat Exchanger

Flow Arrangement 1. Counterflow: Fluids move in opposite directions, maximizing heat transfer.Parallel flow: Fluids move in the same direction, usually less efficient than counterflow. 2. Crossflow: One fluid flows perpendicular to another, an option for compact designs.

Regulations and Standards Must adhere to applicable engineering standards, which can vary by industry (e.g., ASME, TEMA standards).

Operational Considerations

Components

Applications Tube bundles are used in a wide range of applications where heat transfer is required. Some common applications include:

|

||||||||||

| Product Tags: ASME U Stamp Tube Bundle Customized Tube Bundle Oil Refining Tube Bundle |

|

U Bend Tube Bundle , Stainless Steel U Tube Type Fuel Oil Heater |

|

ASME U Stamp Customized Heat Exchanger Steel Tube Bundle For Oil Refining |

|

Heat Exchanger Tube Bundle D-E1 A ASME SA213 T11 U Bend Tube With ASME SA-516 GR.70 (N, FGP) Tubesheet ASME U STAMP |

|

Tube Bundle ASME U STAMP D-E05C ASME SA179 Carbon Steel Seamless Tube With ASME SA266 Gr.2N Tubesheet |

|

ASME U Stamp Customized Tube Bundle Steel Heat Exchanger Seamless Tube |

|

Stainless Steel / Carbon Steel / Copper Alloy Tube Bundle For Shell And Tube Heat Exchanger |