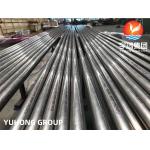

ASTM A213 T5 Alloy Steel Seamless Tube For Heat Recovery Boilers

|

|

ASTM A213 T5 Seamless Tube Chemical Composition

ASTM A213 T5 Applications and Reasons The ASTM A213 T5 alloy steel seamless tube is specifically engineered for demanding high-temperature and corrosive environments. Below are detailed, industry-specific applications where its properties make it indispensable: 1. Power Generation: Superheaters & Reheaters

Why T5?

2. Petrochemical Refineries: Hydrocracker Units

Why T5?

3. Chemical Processing: Sulfuric Acid Production

Why T5?

4. Steam Methane Reforming (Hydrogen Production)

Why T5?

5. Coker Units in Oil Refineries

Why T5?

6. Waste-to-Energy Plants

Why T5?

7. Feedwater Heaters in Nuclear Plants

Why T5?

8. Ethylene Cracking Furnaces

Why T5?

9. Key Advantages in These Applications

|

||||||||||||||||||||||

| Product Tags: Boiler Alloy Steel Seamless Tube ASTM A213 T5 Alloy Seamless Tube Heat Recovery Alloy Steel Seamless Tube |

|

ASTM A335 Grade P22 Alloy Steel Seamless Tube For Boiler and Superheaters |

|

ASTM B407 / ASME SB407 N08811 Alloy Steel Tube For High Temperature |

|

ASTM B163 Monel 400 UNS N04400 Seamless Nickel Copper Alloy Tube Bright Surface |

|

ASTM A335 /ASME SA335 Alloy Steel Seamless Tubes P11 / P12 / P22 / P5 /P9 / P91 / P92 Size 1/2" To 24" NPS |

|

Asme Sa213 T1 Asme Sa209 T1 Seamless Boiler Tubes |

|

AD2000 Asme Sa213 T11 Alloy Steel Seamless Tubes |