Industrial Forced Draft Air Cooler | High Efficiency Heat Exchanger

|

|

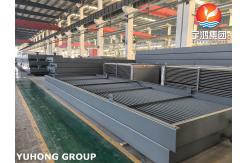

Industrial Forced Draft Air Cooler | High Efficiency Heat Exchanger What is an air cooler? An air cooler, also known as an evaporative cooler or swamp cooler, is a device that cools air through the natural process of water evaporation. Unlike air conditioners (ACs), which use refrigerants and compressors, air coolers are energy-efficient, eco-friendly, and ideal for dry climates. They are widely used in residential, commercial, and industrial settings due to their cost-effectiveness and simplicity. Yuhong Group is a professional enterprise specializing in the production of air coolers, heat exchangers and pressure vessels, if you have any demand please feel free to contact us. Working Principle

-Warm air is drawn into the cooler by a fan. -The air passes through water-saturated cooling pads, where water evaporates, absorbing heat and lowering the air temperature. -The cooled, humidified air is then circulated into the room. Key Components Cooling Pads: Made of absorbent materials (e.g., cellulose or wood shavings) to hold water. Water Reservoir: Stores water, often with a capacity of 10–50 liters. Water Pump: Circulates water from the reservoir to wet the pads. Fan: Draws air through the pads and distributes cooled air. Control Panel: Adjusts fan speed, timer, and cooling modes. Types of Air Coolers Portable: Compact, movable units for homes or small spaces. Window-Mounted: Fixed in windows for localized cooling. Industrial: High-capacity units for factories, warehouses, or outdoor events. Hybrid Models: Combine evaporative cooling with ice compartments for enhanced cooling. Advantages Energy Efficiency: Consumes 80% less energy than ACs (typically 100–200 watts). Cost-Effective: Lower purchase and operational costs. Eco-Friendly: Uses water, not harmful refrigerants. Humidity Boost: Ideal for arid regions, improving indoor air comfort. Ventilation: Works best in open spaces, allowing fresh air circulation. Disadvantages Climate Dependency: Less effective in high-humidity areas. Water Use: Requires regular refilling and maintenance. Maintenance Needs: Pads and reservoirs need cleaning to prevent mold or bacterial growth. Limited Cooling Range: Cools areas by 10–15°F (5–8°C) in dry climates, less in humid regions. Applications Residential: Homes, apartments, and patios. Commercial: Offices, shops, and outdoor events (markets, sports venues). Industrial: Factories, workshops, and greenhouses. Temporary Use: Construction sites or emergency cooling. Comparison with Air Conditioners Cooling Method: Air coolers use evaporation; ACs use refrigerants. Energy Use: Air coolers consume far less electricity. Humidity: Coolers add moisture; ACs dehumidify air. Environment: Coolers are greener (no CFCs). Space Suitability: Coolers excel in dry, open areas; ACs work in sealed, humid environments. Maintenance Tips Regular Cleaning: Replace/clean cooling pads monthly; disinfect tanks to prevent algae. Water Management: Use clean water, drain when not in use, and descale if needed. Inspect Components: Check pumps and fans for functionality. Seasonal Storage: Dry the unit before long-term storage. Conclusion Air coolers offer a sustainable, economical cooling solution for dry climates, combining simplicity with effectiveness. While they have limitations in humid regions, their low energy use, environmental benefits, and versatility make them a preferred choice for many users. Proper maintenance ensures longevity and optimal performance. |

| Product Tags: Industrial High Efficiency Air Cooler Industrial Air Cooler High Efficiency Air Cooler |

|

Oil Refinery Air Cooler API 661 ASME SEC VIII Div-1 |

|

Industrial Forced Draft Air Cooler | High Efficiency Heat Exchanger |

|

API661 Air Fan Cooled Dosh Mol TRCU For Russia CRN Canada |

|

Air Cooler Heat Exchanger API 661 For Power Generation Plants ISO 13706 |

|

Forced Draft Horizontal Air Cooler With Finned Tube API Forced Draught |

|

Forced Draft Horizontal Air Cooler Air Cooled Heat Exchanger API 661 ISO 13706 |