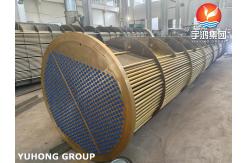

Copper Alloy Steel Heat Exchanger Bundle C12200 C70600 For Maximum Heat Transfer

|

|

Copper Alloy Steel Heat Exchanger Bundle C12200 C70600 for Maximum Heat Transfer

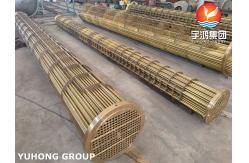

Tube bundle heat exchanger is a typical heat exchange equipment that makes two fluids with different temperatures exchange heat. Through this device, one fluid can be cooled and another fluid can be heated to meet their respective needs. The equipment is widely used in chemical, petroleum, pharmaceutical, energy and other industrial sectors, and is one of the indispensable important equipment in chemical production.

Tube bundle

The fluid channel composed in the heat exchange tube of the tube bundle heat exchanger is called the tube path, and the fluid channel composed outside the heat exchange tube is called the shell path. The working medium enters a heat transfer tube through an inlet nozzle at the end of the head, and the flow can realize a one-pipe, two-pipe and four-pipe structure according to the technological requirements; The other type of working medium enters the shell through an inlet nozzle at one end of the shell and is evenly distributed outside the heat transfer tube, and its flow state can be provided with different types and numbers of baffles in the bundle according to the process requirements. Two different temperature of the working medium into the heat exchanger, the relatively high temperature of the working medium through the heat exchange tube wall to transfer heat to the relatively low temperature of the working medium, the relatively high temperature of the working medium is cooled, the relatively low temperature of the working medium is heated, and then to complete the goal of the two fluid heat exchange process

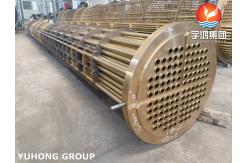

Heat exchanger tube bundle is the core component of tubular heat exchanger, its main functions are as follows:

1.Support pipe: The tube bundle provides a stable structural foundation to ensure

the stability of the overall structure of the heat exchanger. The

position and Angle of the tube bundle have an important effect on

the heat transfer efficiency, so it needs to be accurately

calculated and analyzed during the design and installation. 3.Heat transfer: The tube bundle is a channel for the hot medium to transfer heat to another medium to achieve cold and heat exchange. The material, inner diameter and arrangement of the tube bundle will affect the heat transfer efficiency. Metal pipes such as copper, steel, stainless steel, etc. are often used to make tube bundles so that they can withstand high temperature and high pressure environments. 4.Cleaning and maintenance: Because the tube bundle is the core part of the heat exchanger, over time, it is easy to accumulate dirt and scale, affecting the heat transfer efficiency. Therefore, the tube bundle design should take into account the convenience of cleaning, and sometimes include easy to replace parts, so as to facilitate regular maintenance. 5.Improve energy efficiency: Through heat exchange, the tube bundle can convert waste heat into usable heat energy, improve energy efficiency and reduce energy consumption. 6.Maintaining temperature balance: In industrial production, heat exchangers help transfer heat between different media and maintain temperature balance, which is essential to ensure production efficiency and quality. 7.Improve equipment efficiency: In some equipment, such as steam turbines, tube bundles help cool and reduce pressure to improve the efficiency of the equipment and extend its service life. 8.Seal: The tubular heat exchanger design includes two types of seal: the seal between the tube bundle and the tube plate and the seal between the tube bundle and the shell. These seals need to have good temperature resistance, corrosion resistance and pressure resistance to ensure the long-term stable operation of the heat exchanger.

|

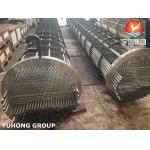

| Product Tags: Heat Exchanger Tube Bundle C12200 Copper Alloy Steel Bundle Heat Transfer Copper Alloy Steel Bundle |

|

Heat Exchanger Tube Bundle D-E1 A ASME SA213 T11 U Bend Tube With ASME SA-516 GR.70 (N, FGP) Tubesheet ASME U STAMP |

|

U Bend Tube Bundle , Stainless Steel U Tube Type Fuel Oil Heater |

|

ASME U Stamp Customized Heat Exchanger Steel Tube Bundle For Oil Refining |

|

Tube Bundle ASME U STAMP D-E05C ASME SA179 Carbon Steel Seamless Tube With ASME SA266 Gr.2N Tubesheet |

|

ASME U Stamp Customized Tube Bundle Steel Heat Exchanger Seamless Tube |

|

Stainless Steel / Carbon Steel / Copper Alloy Tube Bundle For Shell And Tube Heat Exchanger |