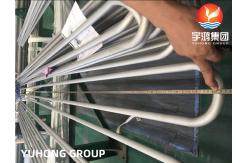

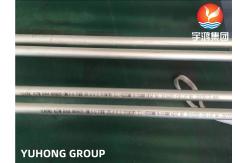

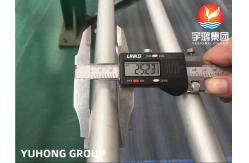

ASTM B444 Nickel Alloy Steel UNS NO6625 SMLS Bend U Tubes

|

|

ASTM B444 Nickel Alloy Steel UNS NO6625 SMLS Bend U Tubes

UNS N06625 products are furnished in two grades of different heat-treated conditions:

Grade 1 (annealed)—Material is normally employed in service temperatures up to 1100°F (593°C). Grade 2 (solution annealed)—Material is normally employed in service temperatures above 1100°F (593°C) when resistance to creep and rupture is required.

(Note 1:Hot-working or reannealing may change properties significantly, depending on working history and temperatures.)

Chemical Analysis Tension Corrosion Test Mechanical Tests: Flattening test, Flaring test, Flange test, Hardness Test and Hydrostatic test Reverse-bend and Re. flat tests Eddy Current Testing Visual Inspection Air Under Pressure Test

Chemical Composition UNS NO6625

Mechanical Property UNS NO6625

*Note: Not applicable to outside diameters under 1⁄8 in. (3.2 mm) and to wall thicknesses under 0.015 in. (0.38 mm). B Hot forming quality pipe and tubing is furnished to chemical requirements and surface inspection only. No tensile properties are required.

D: Annealed at 1600°F (871°C) minimum. E: Solution annealed at 2000°F (1093°C) minimum, with or without subsequent stabilization anneal at 1800°F (982°C) minimum to increase resistance to sensitization.

*Gas and Oil Processing *Pharmaceutical Equipment *Chemical Equipment *Power Generation *Sea Water Equipment *Petrochemicals *Heat Exchangers / Condensers / Boiler *Specialty Chemicals *Pulp and Paper Industry

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM A213 TP304L Austenitic Stainless Steel Seamless U Bend Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

U Bending ASTM A213 TP304L Stainless Steel For Boiler and Heat Exchanger |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |