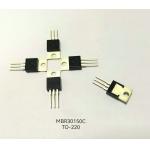

High Current Resistance Schottky Diode For High Frequency Switch

Power Supply

MBR20100.pdf

The internal circuit structure of a typical Schottky rectifier is

based on an N-type semiconductor substrate, on which an N-epitaxial

layer with arsenic as a dopant is formed. The anode uses materials

such as molybdenum or aluminum to make the barrier layer. Silicon

dioxide (SiO2) is used to eliminate the electric field in the edge

area and improve the withstand voltage value of the tube. The

N-type substrate has a very small on-state resistance, and its

doping concentration is 100% higher than that of the H-layer. An N+

cathode layer is formed under the substrate to reduce the contact

resistance of the cathode. By adjusting the structural parameters,

a Schottky barrier is formed between the N-type substrate and the

anode metal, as shown in the figure. When a forward bias is applied

to both ends of the Schottky barrier (the anode metal is connected

to the positive pole of the power supply, and the N-type substrate

is connected to the negative pole of the power supply), the

Schottky barrier layer becomes narrower and its internal resistance

becomes smaller; otherwise, if When a reverse bias is applied to

both ends of the Schottky barrier, the Schottky barrier layer

becomes wider and its internal resistance becomes larger.

Features

1. Common cathode structure

2. Low power loss, high efficiency

3. High Operating Junction Temperature

4. Guard ring for overvoltage protection,High reliability

5. RoHS product

Applications

1. High frequency switch Power supply

2. Free wheeling diodes, Polarity protection applications

ABSOLUTE RATINGS (Tc=25°C)

Parameter | Symbol | Value | Unit |

Repetitive peak reverse voltage | | | |

Maximum DC blocking voltage | | | |

Average forward current | TC=150°C (TO-220/263/252 )TC=125°C(TO-220F) | per device per diode | | | |

Surge non repetitive forward current 8.3 ms single

half-sine-wave (JEDECMethod) | | | |

Maximum junction temperature | | | |

Storage temperature range | | | |