Alloy And Metal 11mJ Portable Hardness Tester With Impact Device D

|

|

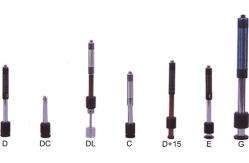

Impact Devices for Hardness Tester, Portable Hardness Tester for Alloy and Metal

Other type of impact devices

Testing conditions: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Type of impact device | DC(D)/DL | D+15 | C | G | E |

Impacting energy Mass of impact body | 11mJ 5.5g/7.2g | 11mJ 7.8g | 2.7mJ 3.0g | 90mJ 20.0g | 11mJ 5.5g |

Test tip hardness: Dia. Test tip: Material of test tip: | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 5mm Tungsten carbide | 5000HV 3mm synthetic diamond |

Impact device diameter: Impact device length: Impact device weight: | 20mm 86(147)/ 75mm 50g | 20mm 162mm 80g | 20mm 141mm 75g | 30mm 254mm 250g | 20mm 155mm 80g |

Max. hardness of sample | 940HV | 940HV | 1000HV | 650HB | 1200HV |

Mean roughness value of sample surface Ra: | 1.6μm | 1.6μm | 0.4μm | 6.3μm | 1.6μm |

Min. weight of sample: Measure directly Need support firmly Need coupling tightly |

>5kg 2~5kg 0.05~2kg |

>5kg 2~5kg 0.05~2kg |

>1.5kg 0.5~1.5kg 0.02~0.5kg |

>15kg 5~15kg 0.5~5kg |

>5kg 2~5kg 0.05~2kg |

Min. thickness of sample Coupling tightly Min. layer thickness for surface hardening |

5mm

≥0.8mm |

5mm

≥0.8mm |

1mm

≥0.2mm |

10mm

≥1.2mm |

5mm

≥0.8mm |

Size of tip indentation

| ||||||

Hardness 300HV | Indentation diameter Depth of indentation | 0.54mm

24μm | 0.54mm

24μm | 0.38mm

12μm | 1.03mm

53μm | 0.54mm

24μm |

Hardness 600HV | Indentation diameter Depth of indentation | 0.54mm

17μm | 0.54mm

17μm | 0.32mm

8μm | 0.90mm

41μm | 0.54mm

17μm |

Hardness 800HV | Indentation diameter Depth of indentation | 0.35mm

10μm | 0.35mm

10μm | 0.35mm

7μm | --

-- | 0.35mm

10μm |

Support rings for Shaped Materials:

Other type of support rings

No. | Type | Sketch of non-conventional Supporting ring | Remarks |

1 | Z10-15 | For testing cylindrical outside surface R10~R15 | |

2 | Z14.5-30 | For testing cylindrical outside surface R14.5~R30 | |

3 | Z25-50 | For testing cylindrical outside surface R25~R50 | |

4 | HZ11-13 | For testing cylindrical inside surface R11~R13 | |

5 | HZ12.5-17 | For testing cylindrical inside surface R12.5~R17 | |

6 | HZ16.5-30 | For testing cylindrical inside surface R16.5~R30 | |

7

| K10-15 | For testing spherical outside surface SR10~SR15 | |

8 | K14.5-30 | For testing spherical outside surface SR14.5~SR30 | |

9 | HK11-13 | For testing spherical inside surface SR11~SR13 | |

10 | HK12.5-17 | For testing spherical inside surface SR12.5~SR17 | |

11 | HK16.5-30 | For testing spherical inside surface SR16.5~SR30 | |

12

| UN | For testing cylindrical outside surface, radius adjustable R10~∞ |

|

Non Destructive Uci Portable Ultrasonic Hardness Tester For Metals |

|

Color Lcd Rechargeable Battery Portable Hardness Testers For Metal |

|

TFT Screen Lcd Portable Metal Hardness Tester For Steel |

|

Color Lcd Rechargeable Battery Portable Hardness Tester Customized Material For Metals |

|

AA Battery Portable Hardness Tester Cylindrical Spherical Outside And Inside Surface Metal Durometer |

|

ASTM D3363-00 Pencil Scratch Method Film Hardness Pencil Coating Hardness Tester |