Precision ABS Profilometer Surface Roughness Tester Customization

|

|

Surface Roughness Equipment Surface Roughness Contour Graph Profilometer Testing Machine

1.Product name:Surface Roughness Profiler Integrated Machine2.Product model:SRT-7150, Brand: HUATEC3. Product photo

4.Key advantages

5. Instrument description and measurement range:

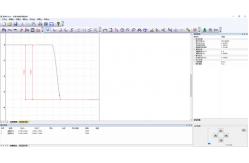

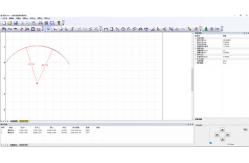

# SRT-7150 is an integrated measuring machine equipment for surface roughness and contour measurement. # The surface roughness and profile of various workpieces are measured and analyzed by using high precision grating measurement system, high precision grinding guide rail, high performance non-contact linear motor, high performance roughness measurement module, high performance computer control system technology and perfect multi-functional software. # The device can measure various parameters of various mechanical parts, such as plain line and cross section profile parameters, surface waviness parameters, roughness parameters and so on. # It can measure the straightness, inclination, angle processing, circle processing ( distance from straight line to tangent line, distance from circle center to circle center, radius of arc, distance from intersection point to circle center, distance from circle center to straight line ), point line processing ( distance from intersection point to straight line, distance from intersection point to circle center, intersection point of two straight lines, distance from intersection point to intersection point ), logarithmic curve, groove width, groove depth, groove edge distance, groove center distance, inclination, horizontal distance, vertical distance and other shape parameters of various parts. # It is suitable for bearing industry, mechanical processing, automobile, motorcycle, precision hardware, precision tools, molds, tools, optical components and other industries.

6.Application cases:7.Product technical characteristics:(1)High precision, high stability, high repeatability, long service life;

(2) Intelligent software system:The instrument operation interface is friendly, the operator can easily master the instrument operation, and the use is very simple.

1 ) The practical measurement software design experience accumulated by the company for many years provides customers with a simple, practical and fast operation experience ; 2 ) Powerful, automatic processing of data, print reports of various formats, automatic display, print, save, query measurement records ; the data can be archived or printed centrally without occupying the verification operation time. 3 ) The measurement range is wide, which can meet the special measurement function of almost all types of workpiece contour measurement, including special workpiece screw, bearing, thread and so on. 4 ) The measured section can be selected automatically and manually for evaluation, and the software function can be customized according to customer requirements ; 5 ) Using computer large capacity database storage, can record all the verification results.

8.Environmental requirements for use:

9.Technical parameters:

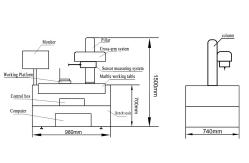

Note: The above technical parameters can be adjusted according to the actual needs of users. You are welcome to consult our technicians on various issues.10.Equipment size:11.Product standard configuration:

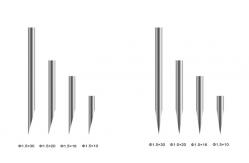

12. Optional configuration1,Different specifications and test needles2. Multi-direction and multi-force working platform

Two-axis platform: rotation and yaw; Z-axis rotation: 360 °, minimum subdivision is 1 ', with locking function; Y-axis tilt: Y-axis deflection, measuring range 45 °, minimum subdivision 0.1 °; Opening of flat pliers: 85 mm; Overall size of the bench (length x width x height): 170X170X160mm; Total weight: 14KG; Maximum load: 20KG

3,Multi-function V block

Size: 75 * 35 * 24mm; Remarks: used for positioning small shaft parts, with clamping function

4,Multifunctional fixture

13. Delivery and acceptance1, Delivery

2, Installation and training

3, Check before acceptance

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Customization Surface Roughness Tester Precision Surface Roughness Tester ABS Profilometer Surface Roughness Tester | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Differential Inductive Sensor Surface Tester Roughness Motif Waviness Profile Equipment |

|

Flatness Measuring Surface Roughness Tester Portable |

|

Metric / Imperial Inductance Surface Roughness Instrument SRT-5100S |

|

Lcd Display Bluetooth Surface Roughness Tester ASTMD-4417-B US Navy NSI 009-32 Portable |

|

ISO DIN ANSI Surface Roughness Gauge JIS DSP Chip Control OLED 22 Parameters Ra |

|

Rugged Compact Iso Portable Surface Roughness Tester |