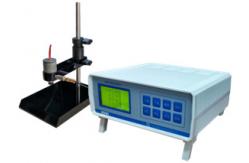

0.1μM Non Metal Coulometric Coating Thickness Gauge Electronic Paint Thickness Gauge

|

|

0.1μM Non Metal Coulometric Coating Thickness Gauge Electronic Paint Thickness Gauge

TG-100D coulometric thickness gauge, using anode dissolution coulomb method, conforms to ISO2177 standard. It can measure chromium, nickel, copper, zinc, tin, silver, gold, cadmium and other metal coatings, nickel alloy coatings, composite coatings (such as Cr/Ni/Cu) and multilayer nickel coatings.

The electrolytic thickness gauge adopts the principle of Coulomb

method to measure the thickness of the coating, so it is also

called Coulomb method thickness gauge or electrolytic thickness

gauge. It is an ideal instrument for measuring various single metal

coatings and multi-metal coatings on metal (such as steel, copper,

zinc alloy or non-metal (such as plastic, neodymium iron boron)

substrates. It is widely used in the following industries:

automobiles, motorcycles, Bicycles, sports equipment, aerospace and

navigation, electronic appliances, high and low voltage switches,

household hardware, sanitary ware, kitchenware, plastic plating,

standard rooms, NdFeB, security products, cables and other

industries, technical supervision departments and scientific

research institutions .

Such as mobile phone and camera buttons, car knobs, hardware tools,

electronic and electrical parts, showers, faucets, shelves, sports

equipment, bicycles, standard parts, kitchen supplies, toilet

supplies, locks, door handles, car signs, doors Cabinet

accessories, motorcycle brackets, mufflers, car signs, wind grills,

car door locks, car handles, car interior parts, connectors, wires,

welding wires, neodymium iron boron plating, etc. are used in

automobiles, motorcycles, sanitary ware and other industries The

STEP function is measured simultaneously to the thickness and

potential difference of multilayer nickel. At this time, use TG-G

electrolytic thickness gauge to complete.

Coating substrate: metal, non-metal

All models guide:

TG-100D and TG-100E

The difference between TG-100D and TG-100E is: TG-100D has no printing function, no clock display, other properties are the same.

TG100-E economic model 1. The preset standard plating types are: decorative chromium, hard chromium, nickel, copper (copper on iron or non-metallic substrate), zinc, tin, silver, and gold 8 plating types. If you want to test other plating types, you must modify the preset plating types. For example, if you need to test electroless nickel (customers may not test silver), you can change silver to electroless nickel. 2. Standard configuration Probe: diameter 2.4mm (also 1.7mm, 1.2mm, 1.0mm, 0.8mm optional) The machine is equipped with only one type probe, so customer need to tell the smallest workpiece size, try to choose a large probe which the accuracy will be better 3 . Potential difference cannot be measured 4. Simple information can be printed: plating type, thickness, test time

TG-100G all-round type 1. It can complete all the functions of TG-100E type 2. It can measure the potential difference of multi-layer nickel 3. It can use two kinds of probes, usually 2.4mm and 1.7mm. 4. The data can be stored in the computer and read at any time. 5. Printable A4 testing report 1. It can complete all the functions of TG-100E 2. It can change to a variety of probes, usually 2.4mm and 1.7mm 3. It can easily complete wire measurement without conversion factor 4. Print complete test data: every Sub-data, maximum value, minimum value, average value, standard deviation, tester, test time, test times. Multi-plated test data can be displayed in one report at the same time. 5. Potential difference cannot be measured.

Scope of application

2. TG-100G is more focused on the automobile, motorcycle, and sanitary ware industries, because these industries will use the potential difference function. And neodymium iron boron industry, to solve the test problems of the underlying nickel. Automobiles such as: signs, car door locks, car handles, car interior parts, motorcycles such as mufflers, motorcycle brackets, sanitary wares such as: mixing water valves, towel racks, neodymium Iron-boron: mainly nickel-copper-nickel electroplating 3. TG-208 is similar to TG-100E type in application, easy operation, complete functions, rich printing content, and easy operation for wire testing is its biggest highlight. No domestic product can compare with it.

|

| Product Tags: coulometric coating thickness gauge non metal coulometric thickness tester 0.1μm Coating Thickness Gauge |

|

Tin Plating On Copper Galvanized Layer Coating Thickness Gauge Multifunction |

|

Paint Coating Thickness Gauge Weight Measurement Mini Usb Interface For Communication |

|

13mm Enamel Plastic Spraying Coatings Anti Corrosion Fireproof Coating Thickness Gauge TG-6008 |

|

300 Degree Celsius Paint Coating Thickness Gauge High Temperature Spray Layer Paint Layer |

|

Inbuilt Printer Dry Film Paint Elcometer Coating Thickness Gauge Tg110 |

|

Metal Coating Electrolytic 35μM Coulometric Thickness Tester |