Round / Square Bottle Labeling Machine For Liquid Water Line / Filling / Bottling Machine

|

|

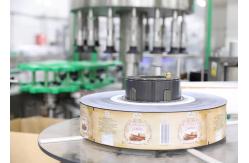

Automatic OPP Roll Fed Hot Melt Glue Labeling Machine for Round/Square Liquid Water Line/Filling/Bottling Machine

Technical parameters:

|

||||||||||||||||||||||||||||||||||||||||

| Product Tags: bottle label machine bottle labelling machine |

|

Automatic Round Bottle Labeling Machine 110V PVC Shrink Sleeve Film |

|

Fully Automatic Adhesive Sticker Label Printing Machine For Bottles |

|

220V Rolling Round Bottle Sticker Labeling Machine 9000 bottles/Hour |

|

220V 380V Round Bottle Sticker Labeling Machine Full Automatic |

|

Rotary Water Carbonated Drink Bottles Type Sticker Labeling Machine Three Sides |

|

Full Auto Self Adhesive Three Side Labeling Machine For Beer Bottle |