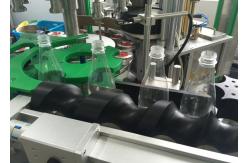

Small Capacity Hot Melt Opp Labeling Machine , Automatic Bottle Labeler 5000BPH

|

|

Small Capacity Hot Melt Opp Labeling Machine , Automatic Bottle Labeler 5000BPH

Machine function: Position on the round bottle and square bottle to paste OPP, BOPP and paper labels which are rolling without glue. This machine will deliver labels automatically, select and cut labels, glue at both ends of each label, add labels and smooth out labels.

The machine suits for the application of mineral water, beverage, food, washing and other industries to realize labels-cutting, glues-coating and labelling for round bottles and square bottle.

Electric cabinet

1. General power supply switch 2. Touch screen 3. Emergency stop switch The main control circuit of the electric cabinet integration system is the location for layout and installation of electric components. The electric cabinet is provided with two locks. After unlock them, pull up the lock handle and turn it right to open the cabinet door. The specific operation about the integrated man-machine interface of electric cabinet can be seen in 3.1.

1.3.9. General power supply switch The general power supply switch is located below the electric cabinet at front of the machine (Figure 9). Turn the switch in the clockwise direction to the position of ON to connect the power, and turn the switch in the anticlockwise direction to the position of OFF to disconnect the power.

1.3.10. Material-lack sensor Inspect whether lacking material during the first transporting period, if lacking material, send a signal to the control system for stop. The machine is provided with the material-lack sensor in order for no single bottle goes into the separating screw stem to result the bottle down.

1.3.11. Emergency stop switch The machine is provided with two emergency stop switches. One is located above the touch screen and the other is located aside the transport line (Figure 9). When an emergency happens, please ensure to press the switch and stop the whole machine. At that moment, the system information section indicates that the emergency stop switch is not on and the frequency inverter alerts! Just turn the top cap of the emergency stop switch in the clockwise direction to set the emergency switch on.

1.3.12. Touch screen With Chinese human-computer operation interface, the touch screen is applicable to start/stop the machine, set/adjust various parameters, and indicate/report production information!

1.3.13. System air pressure inspection The machine is provided with an air pressure inspection device (Figure 9). When the system air pressure is lower than the system assumed value and insufficient to ensure the system run normal, the machine may stop voluntarily, and the touch screen information section indicates an alert report of <air pressure insufficient>!

|

||||||||||||||||||||||

| Product Tags: bottle label machine bottle labelling machine |

|

Automatic Round Bottle Labeling Machine 110V PVC Shrink Sleeve Film |

|

Fully Automatic Adhesive Sticker Label Printing Machine For Bottles |

|

220V Rolling Round Bottle Sticker Labeling Machine 9000 bottles/Hour |

|

220V 380V Round Bottle Sticker Labeling Machine Full Automatic |

|

Rotary Water Carbonated Drink Bottles Type Sticker Labeling Machine Three Sides |

|

Full Auto Self Adhesive Three Side Labeling Machine For Beer Bottle |