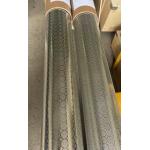

Mechanism Textile Fabric Parts Nickel High Elasticity Printing Rotary For Coating

|

|

Mechanism Textile Fabric Parts Nickel High Elasticity Printing Rotary For Coating

rotary screen Description: Rotary Screen Printing offers stunning print quality on a variety of substrates. Today, there are many options for printing but rotary screen printing still leads the market. Nickel screen with variety specifications and good tenacity, can be repeatly used for several times,suitable for any kind of dyestuff,with even inflitration,it can fit any pattern,specially good at super fine pattern.

Requirements of Rotary Screen Printing

Specification:

Textile Machinery Spare Parts The only factor that determines the production rate is the speed of screen rotation/substrate movement (remember, these values are the same), which is limited primarily by the type and rheology of the ink being used. Productivity Among the biggest attractions of rotary screen printing is its production speed. On a rotary press, images are applied to the entire width of the substrate as the material moves continuously through the printing mechanism--substrate size really has no impact on press speed. Because of the way rotary presses operate, their production rates are reported as linear measurements and typically fall within a range of 100-450 ft/min (30-100 m/min), depending on the model and the specific application.

Not only does this approach reduce printing times, but it also removes the floodbar as a variable from the printing process.As previously noted, the flooding and printing action on a rotary system is all part of the same continuous motion, and separate strokes for these functions are not required.

Users simply thread the desired material into a rotary machine from a reel at one end, and the machine continues to pull more material through as needed.Material handling Because rotary presses work with web-fed materials, they eliminate the need to feed substrates into the press piece by piece, as is common with flatbed units.

printing is a two-step process that involves a pass over the screen

by the floodbar to fill mesh openings with ink, The situation

is a little different with flatbed presses. On a flatbed press,

followed by a squeegee pass to bring the stencil and substrate into

contact for ink transfer. Rotary vs. flat screen printing

Delivery time: within 15 to 25 days

Package: plywood cases or as you required

Rotary screen printing:

|

||||||||||||

| Product Tags: Mechanism Textile Fabric Nickel High Elasticity Textile Fabric Nickel Rotary Textile Fabric Nickel | ||||||||||||

|

Bruckner LK Monforts Textile Machinery Spare Parts Stenter Machine Steel Pin Plates |

|

Blanket Special Screen For Rotary Screen 640 819 914mm Textile Machinery Spare Parts |

|

640 819 Uniform Cutting Edge Accuracy Fabric Rotary Nickel Screen Textile Screen Printing |

|

Nickel Screen Wallpaper Rotary Screen Cylinder Textile Machinery Spare Part |

|

Higher Open Area Textile Fabric Parts Nickel High Elasticity Printing Rotary For Coating |

|

Cylinder Printing Nickel Mesh Roll 640 819 914mm Textile Machinery Spare Parts Rotary Screen |