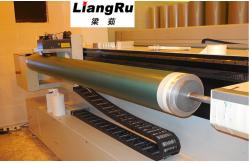

Printing Nickel Screen Textile Machinery Spare Parts Authority Certification

|

|

Printing Nickel Screen Textile Machinery Spare Parts Authority Certification

Textile Machinery Spare Parts:

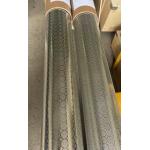

Use 6-7 times stripping by water jet or LEN,by collecting the data from thousand of experiments.Our screen also SULFUR-FREE and with excellent brittleness,a convenient way to test the brittleness is the so-called "lighter test": a piece of screen sample burnt by lighter flame for 10 seconds, bend the screens sample to see if it breaks at the burnt spot. our screens will not broken.Open area up to 18% ,there is no factory in china can make it except our factory,it help smooth throughout of dyestuff paste, so that printing speed and efficiency of printing machine can be ascended,experiments have proved that up to 19% of paste volume can be saved at multiple printing mills around the world.

Users simply thread the desired material into a rotary machine from a reel at one end, and the machine continues to pull more material through as needed.Material handling Because rotary presses work with web-fed materials, they eliminate the need to feed substrates into the press piece by piece, as is common with flatbed units. specificationsbear high temperature Excellent toughness & elasticity,

Our nickel screen,with variety spectifications and good

tanacity,can be repeatly used for several times.

Screen Specification:

Not only does this approach reduce printing times, but it also removes the floodbar as a variable from the printing process.As previously noted, the flooding and printing action on a rotary system is all part of the same continuous motion, and separate strokes for these functions are not required.

printing is a two-step process that involves a pass over the screen

by the floodbar to fill mesh openings with ink, The situation

is a little different with flatbed presses. On a flatbed press,

followed by a squeegee pass to bring the stencil and substrate into

contact for ink transfer. Rotary vs. flat screen printing

Delivery time: within 15 to 25 days

Package: plywood cases or as you required

Rotary screen printing:

|

||||||||||||

| Product Tags: textile machinery parts stenter machine spares Textile Machinery Printing Nickel Screen | ||||||||||||

|

Bruckner LK Monforts Textile Machinery Spare Parts Stenter Machine Steel Pin Plates |

|

Blanket Special Screen For Rotary Screen 640 819 914mm Textile Machinery Spare Parts |

|

640 819 Uniform Cutting Edge Accuracy Fabric Rotary Nickel Screen Textile Screen Printing |

|

Nickel Screen Wallpaper Rotary Screen Cylinder Textile Machinery Spare Part |

|

Higher Open Area Textile Fabric Parts Nickel High Elasticity Printing Rotary For Coating |

|

Cylinder Printing Nickel Mesh Roll 640 819 914mm Textile Machinery Spare Parts Rotary Screen |