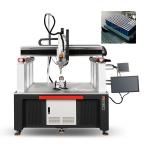

1000W - 6000W 4 Axis Multifunctional Continuous Optic Fiber Laser Welding Machine

|

1000W - 6000W 4 Axis Multifunctional Continuous Optic Fiber Laser Welding Machine4 Axis Automatic Fiber Laser welding machine uses high-energy laser

pulses to locally heat the material in a small area. The energy of

the laser radiation diffuses into the material through heat

conduction, and the material is melted to form a specific molten

pool. It is a new type of welding method, mainly for the welding of

thin-walled materials and precision parts, which can realize spot

welding, butt welding, stick welding, sealing welding, etc. The

welding speed is fast, no treatment is needed after welding, and

the quality of the weld is high. , can be precisely controlled,

small focus spot, high positioning accuracy, easy to automatic. Continuous fiber laser welding VS Yag pulse laser welding

1. The fiber continuous laser welding machine uses 500W-2000W laser, the laser has a long service lifeand the service life can reach 100,000 hours.

2. The electro-optic conversion efficiency is high, and the energy of the power shaving is 25%-30% converted into laser, and the fiber conversion rate is more than 10 times that of the YAG laser.

3. The whole machine has no consumables. YAG pulse welding machine should replace the xenon lamp and lens regularly.

4. The whole machine has low energy consumption, saves electricity, high stability, maintenance-free, and low cost of use.

5. The laser welding energy density is high, welding speed is four times that of YAG pulse.the weld seam is thin,the thermal deformation is small, and the heat affected zone is narrow and deep.

6. Optical fiber output, easy to match with automated workbench or robot to improve production efficiency,and can meet 24 hours of continuous work.

7. Customizable large workbench and XYZ axis travel.

ApplicationWeldable material: The weldable material is metal equivalent

material (all kinds of carbon steel, stainless steel, aluminum

alloy, gold, silver, precious metals, etc.), and also can be

dissimilar metals (copper to steel, copper to titanium, nickel to

titanium, etc.). High-precision machining such as spot welding,

butt welding, and overlap welding of thin material parts can be

achieved.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 4000W Fiber Laser Welding Machine 3000W Fiber Laser Welding Machine 2000w fiber laser welder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

60W 100W 120W JPT Pulse Fiber Laser Welding Machine For Battery |

|

Battery Shell Automatic Fiber Laser Cutting Machine 120M/MIN |

|

60W/100W/150W/300W QCW Fiber Laser Welding Machine For Lithium Battery Pack Welding |

|

Automatic Lithium Prismatic Battery Pack Laser Welding Machine With gantry |

|

Taiyi Laser Automatic Battery Tab Welder Laser Welding iron phosphate battery are tapped |

|

Gantry 18650 21700 32650 Battery Pack Laser Welding Machine |