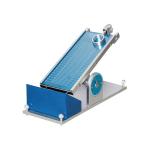

Temperature Adhesive Tape Peel Retention Tester With Microcomputer P.L.D

|

|

Professional Manufacturer Temperature Adhesive Tape Peel Retention Tester Usage: Apply to under the continuous heating conditions,Measured parallel to the direction of a certain weight under pressure sensitive adhesive tape adhesive ability.Shear strength (resistance to shear force) is the adhesive tape as the base material used in the same plane when the ability of resistance to static force. The significance of the application:Shear failure temperature refers to when the sample is load weight, its temperature bonding shear failure of the region. Overview of the test test method Solution according to control the speed of a tape is paste in the standard of sheet metal.The steel plate installed in a vertical adjustable heating furnace, and then put a standard quality weight hanging on the free end of the tape.The temperature of the heating furnace to control good speed stability, and determination of shear failure.

Specification: Temperature control range:Normal~300℃ Control methods:Microcomputer P.L.D automatic temperature control algorithms. Temperature resolution:0.1℃ unit showing. Control accuracy:±0.3 ℃. Heating speed:0.5℃/min Distribution of precision:±1%(200℃). Weight:1kg, 9groups. Electric control: specimen harmlessly, buzzer rang (with switch), and automatically break hot Manufacturing material: internal SUS# 304 stainless steel plate, external: paint coating. When counting device: electronic LCD display, automatic retention time, 99999.9 hours (or minute) can be set Weight and size:80kg 140×55×85 cm Power:1Ø, AC 220V/50Hz Test Mehods: Program set the initial heating furnace temperature of 40 ℃, can preheat furnace to the temperature. Will spray a solvent on the test panel, absorb good clean materials used to wipe dry.Repeat this solvent cleaning three times.Finally using MEK or acetone to wipe.Test panel before use must maintain at least 10 minutes in this condition.Less than ten minutes of panel should be cleaned. Samples in the middle of the test at the end of the panel, without any pressure to 24 x 24 mm tape precise coverage area. In order to prevent the solution volume to cutting on the edge of the test plate samples, need to be at the free end of the sample is placed under another same thickness or slightly thin panel, in the solution volume before contact with the edge of the panel.With 600 + / - 20 mm/min) signals.a detection rate in the extension direction of the area two times. Put the fixture in the sample free end of the cover, make sure fixture full open on the width of the sample, the uniform load distribution. Pensile clog, allow 2 minutes to 30 + / - wetting time (stay). On the test detection device, make the free end of the vertical test samples, make sure there are no stripping force on the samples. Gently apply load or other agreed load (500 g) on the jig, lest

cause sudden impact on tape samples.According to tape the cohesive strength, choose suitable

tape load, such as for traditional styrene block copolymer (SBC)

pressure sensitive adhesive, selection of load is 500 g, with

strong adhesive, such as acrylic pressure sensitive adhesive,

selection of load is 1000 g.If the type of adhesive is unknown, the

first to use 500 g load.If the tape SAFT is greater than 205 ℃, can

increase the applied loads, on the other hand if SAFT is less than

40 ℃, can reduce the applied loads.Applied load as quickly as

possible to avoid heat loss, but be careful, don't have sudden

impact on tape samples. Close the oven door, start the timer.Note: once the oven door closed, during the test are not allowed to open again. Company information: Established in 2003, Dongguan Kejian Instrument Co., Ltd is a high-tech enterprise which professionally research, develop and produce precise testing instruments and provide a full set of testing solution. Kejian has been constantly providing satisfactory products and service to its customer with professional

technical R&D team, excellent production and high management level for customers. Thus it has been gradually becoming the leading supplier in testing industry. Our main product :Temperature and Humidity Peel Strength Tester for Tape,Adhesive

Shear Strength Tester,Tape Peel Strength Tester,Conputer Type Loop

Tack Tester,Coefficient Of Friction Tester,Adhesive Tapes Shear Adhesion Failure Temperature Tester ,Humidity

and Temperature Tester Chamber,UV Accelerated Weathering Test

Chamber,Industrial Oven,Salt Spray Tester,Continuous Hotmelt

Coating Laminating Machine etc..

Attend the fair: Our company will attend the world's exhibitions every year and have dealers all over the world.The products sell well in Asia, Europe and America.Welcome to our booth. Certifications and letters patent We have CE and IOS certificates. If you need other special certificates, we can also help you Packing &Delivery Packaging Details:Disposable Plastic Apron PE Film Making Machine

uses international standard package, big wooden cases Delivery Time: 10-20 days after received deposit Our services 1. Warranty time: All machines are guaranteed for one year free

that we provide spare components except the wrong operation or

damaged by people on purpose. 2.Teaching services: Our engineers will teach your staff to operate

the machine during the period of installation and commissioning,

and they will not leave until your staff can operate it properly

and normally when it necessary. 3.Certificate services: Complying with our clients' request, we can

provide related certificates to clients freely 4.Maintenance services: If you have any questions or any

malfunction happened,we will reply you within 48 hours . Contact us Contact person:Laura Zeng Contact Number:+86 135 3741 5006(Wechat,Whatsapp) |

| Product Tags: temperature humidity controlled cabinets temperature and humidity controlled chambers |

|

220V 50Hz Power Supply 90-Degree Tape Peel Strength Testing Machine For Compression Testing |

|

10kg High Precision Sensor Double Column Servo Motor Adhesive Shear Force Testing Instrument |

|

High Precision Laboratory Release Film Mobile Phone Protective Film Peel Strength Testing Machine |

|

Label Adhesive Peeling Strength Testing Machine High Accuracy |

|

ISO 7/16″ Tape Rolling Ball Peel Adhesion Test Equipment ASTM D3121 |

|

KEJIAN Tape Adhesion Tester Ball Rolling Ball Tack Test Machine |