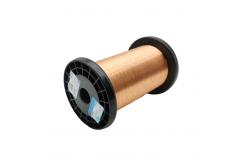

0.35mm Class 155 Winding Wire Enameled Copper Wire

We are one of the pioneers in producing micro thin enameled wires

below 0.03mm in China. Our R & D team has 20 years of market

experience.We have achieved the goal of "zero pinholes after

stretching" for ten years. In 2019, our finest diameter is 0.011mm,

and mass production has been achieved.When the displays return the

transformer industry, we are the No.1 Chinese brand with a share of

cake.We rival the internationally renowned enameled wire brands for

production, technology, raw materials.We surpass them in terms of

"service, quick response"; 30% lower "price" is our advantage. More

and more well-known customers choose us as suppliers-Philips,

Bosch, Panasonic, Samsung ...

Advantages Of Enameled Copper Wire

a) High resistance to heat shock.

b) High temperature.

c) Good performance in cut-through.

d) Suitable for high-speed automated routing.

e) Able to be direct weld, with no pinhole.

f) Resistive to high frequency, wearing, refrigerants and

electronics corona.

g) High breakdown voltage, small dielectric loss angle.

h) Environment-friendly.

Test report

Test Items | Requirements | | Result |

1st Sample | 2nd Sample | 3rd Sample | |

Appearance | Smooth & Clean | OK | OK | OK | OK |

Conductor Diameter | 0.35mm ± | 0.004mm | 0.351 | 0.351 | 0.351 | OK |

0.004mm |

Thickness of Insulation | ≥0.023 mm | 0.031 | 0.033 | 0.032 | OK |

Overall Diameter | ≤ 0.387 mm | 0.382 | 0.384 | 0.383 | OK |

DC Resistance | ≤ 0.1834Ω/m | 0.1798 | 0.1812 | 0.1806 | OK |

Elongation | ≥23% | 28 | 30 | 29 | OK |

Breakdown Voltage | ≥2700V | 5199 | 5543 | 5365 | OK |

Pin Hole | ≤ 5 faults/5m | 0 | 0 | 0 | OK |

Adherence | No cracks visible | OK | OK | OK | OK |

Cut-through | 200℃ 2min No breakdown | OK | OK | OK | OK |

Heat Shock | 175±5℃/30min No cracks | OK | OK | OK | OK |

Solderability | 390± 5℃ 2 Sec No slags | OK | OK | OK | OK |

Insulation Continuity | ≤ 25 faults/30m | 0 | 0 | 0 | OK |