ASTM E1623 Intermediate Scale Calorimeter 1.Product Introduction Intermediate Scale Calorimeter,used to measure the combustion

characteristics of samples vertically exposed to a specific

radiation source 2.Technical parameters - 2.1 The equipment includes a radiant plate, a sample mounting

bracket, a flue gas collection and sample gas collection system, a

gas analysis and data processing system, and a gas supply system;

- 2.2 The radiant panel mounting bracket is welded by a 50*50mm

square tube, and the surface is coated with a black coating, which

can effectively increase the service life. The square tube can be

cooled by cooling water to prevent thermal deformation;

- 2.3 The radiation plate is composed of a high temperature resistant

ceramic plate, and the surface can form a fire-free infrared

radiation source, and the intensity is not less than 50kw/m2;

- 2.4 The size of a single ceramic disc is 95*158mm, 4 pieces form a

module, a total of 27 modules form a radiation source with a size

of 1524*1330mm;

- 2.5 Equipped with pilot burner, which is ignited by electric spark

ignition device;

- 2.6 Each 3 modules are individually equipped with blowing device,

natural gas control device and Venturi mixer;

- 2.7 The sample mounting bracket is welded by carbon steel, which

can withstand high temperature and stably support samples up to

152mm thick;

- 2.8 The sample mounting bracket is installed on the trolley, and

the test sample can be quickly positioned and removed by the rail

on the ground;

- 2.9 Equipped with weighing device, the accuracy is as low as 1g;

- 2.10 Equipped with a water-cooled protective cover to protect the

sample from a surface temperature of less than 100°C before being

exposed to radiation, and can be moved away from the water-cooled

protective cover within 2 seconds through a pneumatic device;

- 2.11 Equipped with a pyrometer to measure the surface temperature

of the radiant plate, with an accuracy as low as 1℃;

- 2.12 Electric heating wire igniter, installed at the bottom and top

of the sample, used to ignite the test sample;

- 2.13 Schmidt-Boelter water-cooled heat flow meter, measuring range

0-50kw/m2, accuracy ±3%;

- 2.14 Heat flow calibration panel, made of 740kg/m3 silicic acid

cover plate, size 1000*1000*12.7mm, 5x5 total 25 calibration holes

arranged on the surface, used to calibrate radiant heat;

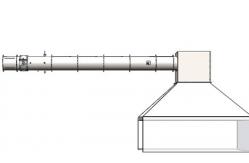

- 2.15 The conical flue gas collector is installed directly above the

weighing table and the sample. The bottom size is 2440mm*2440mm and

the height is 1000mm. The top of the conical flue gas collector is

a square of 900mm*900mm*900mm. *900mm steel plate is installed in

the top square to form a flue gas homomixer;

- 2.16 The shortest length of the stainless steel exhaust pipe is not

less than 5000mm, the diameter is 400mm, and both ends are equipped

with flue gas mixing devices;

- 2.17 The smoke exhaust system has sufficient capacity to collect

all the flue gas generated in the combustion test, the exhaust

volume of the fan is continuously adjustable, and the smoke exhaust

capacity is not less than 8000m3/h;

- 2.18 The exhaust fan is a centrifugal fan, the inner tank is made

of stainless steel, the temperature is not less than 300 degrees,

and the frequency conversion fan is used to adjust the speed;

- 2.19 The ignition of the sandbox burner adopts the surface ignition

method, and does not use spark ignition and other ignition methods

with low ignition success rate.

- 2.20 Imported mass flow controller, the range is 0g/s-7g/s, the

reading accuracy is not less than 1.5%, and the maximum output

power is 300KW;

- 2.21 A pipe with a length of 500mm has three built-in

thermocouples, and the thermocouple installation position is at

least 400mm away from the collector;

- 2.22 The pipeline with a length of 2155mm in the comprehensive

measurement area is equipped with a pressure probe, three

thermocouples, and a gas sampling probe device;

- 2.23 The flue gas sampling system, consisting of soot filters, cold

traps, drying columns, pumps and waste liquid regulators, should be

able to ensure effective collection of flue gas samples and removal

of waste liquid;

- 2.24 Imported diaphragm pump, flow rate: 33L/min, vacuum: 700 ㎜Hg,

pressure: 2.5 bar;

- 2.25 The filter head of the American PARKER soot filter is made of

solid PTFE, with 0.5um PTFE filter material inside;

- 2.26 The filter head of the moisture filter is made of solid PTFE,

and the bottom liquid can be drained through the trap;

- 2.27 Compressor type condenser, cooling capacity 320KJ/h, dew point

stability 0.1 degree, dew point static change 0.1K, protection

grade IP20;

- 2.28 Imported rotameter with a range of 0-1L/min.

- 2.29 Three OMEGA thermocouples, all of which are 0.5mm diameter

armored insulated K-type thermocouples. The contacts should be

located on a circular arc with a radius of (87±5) mm from the axis,

with an included angle of 120 °;

- 2.30 Two sets of two-way probes are connected with imported

pressure sensors with a range of at least (0-100) Pa and an

accuracy of ±2Pa. The response time of 90% output of the pressure

sensor is at most 1s;

- 2.31 The gas sampling probe is connected with the gas regulator and

the O2 and CO2 inlet gas analyzer. The accuracy of the oxygen

analyzer is 0.02%, and the response time is no more than 12

seconds;

- 2.32 The imported oxygen analyzer should be of paramagnetic type

and can measure at least 16%-21%(V/V) 02. The response time of the

oxygen analyzer should not exceed 12s. Within 30min, the drift and

noise of the analyzer No more than 100×10-6. The output of the

analyzer to the data acquisition system should have a maximum

resolution of 100×10-6;

- 2.33 The imported carbon dioxide analyzer should be IR type and can

measure CO2 with a concentration of at least 0%-10%, and the

linearity of the analyzer should be at least 1% of the full scale.

The response time of the analyzer should not exceed 12s. The output

of the analyzer to the data acquisition system should have a

maximum resolution of 100×10-6;

- 2.34 The optical attenuation system is an incandescent light type,

which is installed on the side pipe of the smoke exhaust pipe with

a flexible joint and includes the following devices:

- 2.35 The lamp is an incandescent lamp and is used at a color

temperature of (2900±100)K. The power supply is a stable direct

current, and the current fluctuation range is within ±0.5%

(including temperature, short-term and long-term stability);

- 2.36 Lens system, used to concentrate light into a parallel beam

with a diameter of at least 20mm. The light-emitting hole of the

photocell should be located at the focal point of the lens in front

of it, and its diameter (d) should depend on the focal length (f)

of the lens so that d/f is less than 0.04;

- 2.37 Detector and imported silicon photodiode probe, the

photoelectric detection room has 0.1% linear stability, 10-bit

measurement range, the spectral distribution responsivity of

silicon photodiode is consistent with CIE (illumination curve), the

standard function V(γ) can Achieve at least ±5% accuracy;

- 2.38 The 90% response time of the optical attenuation system should

not exceed 3s;

- 2.39 Data acquisition system (used to automatically record data),

for O2 and CO2, the accuracy is at least 100×10-6 (0.01%), for

temperature measurement, the accuracy is 0.5℃, for all other

instruments, the instrument's full-scale output value 0.1% of 0.1S

for time. Adopt Taiwan Advantech's acquisition module;

- 2.40 The data acquisition system records and stores the following

relevant values at least every 3s:

- Time, s;

- Mass flow rate of propane gas passing through the burner, mg/s;

- The pressure difference of the bidirectional probe, Pa;

- O2 concentration, (V oxygen/V air)%;

- CO2 concentration, (V carbon dioxide/V air)%;

- The three-point temperature value of the comprehensive measurement

area, K.

- 2.41 Standard test software, including various sensor calibration,

system calibration, and software interface for technical

instructions.

- What are calorimeters used?

- Calorimeters are used to measure the volume and heat produced during a certain time interval. The flow is passed through a tank partly filled with water whose

thermal capacity and weight are known before the beginning of the

experiment.

|