Lab Building Materials Flammability Tester , UL1685 Vertical Tray Test Chamber for Cables

|

|

Lab Flammability Testing Equipment , UL1685 Vertical Tray Test Chamber for Cables

Application Apply to check the vertical-tray fire test for determining values

of cable flame propagation and smoke release when the cables are

subjected to a flaming ignition source. (It is nothing to the

purpose of cables, such as the electric power, telecommunications

etc.) Main components including a. Ignition Source control system b.Collection tower and smoke exhaust control system c.Gas pressure and flow control system d.Smoke transmittance and temperature measurement system e.Flame height measurement system

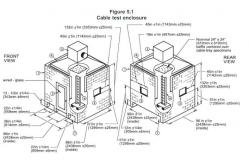

Technical parameters 1. Laboratory: the wall adopts high temperature refractory brick, the inner surface is treated with black, and the wall dimension is W2438 x D2438 x H3353mm; painted 2. Laboratory door: W0.9 x H2m stainless steel frame, toughened glass door; 3. Smoke collecting tower: the inclination angle of 40 degrees, the cube is 914mm; the filter length is 610mm; 4. Observation window: the side length is 457mm, the distance from the bottom to the ground is 1295mm, and the right to the wall is 1143mm. 5. Air inlet: 559 x 343mm, 914 x 305mm, 2438 x 343mm; 6. Exhaust pipe: L9000 * dia 406mm, installed in the tower on the right side of the cube collection level; 7. Burning ladder: high 2400mm, L305 * W25 * D25. The 299mm distance between two square; 8. A: there are 242 hole L341mm * D30mm; 9. Gas flow: 13.2L/mim, standard pressure and temperature, mass flow control; 10. Air flow: 76.8L/mim, standard pressure and temperature, mass flow control; 11. Flow detection: the differential pressure flow meter is used to measure the flow rate of the exhaust pipe, providing the basis for controlling the speed of the fan. 12. Transmittance: the silicon photocell detects the smoke density of the sample when the sample is burned. 13. Flame height: infrared visible light in real time indicates the current flame height; 14. Special software: can draw the real time pipeline flow, smoke density, flame height and other data to draw the curve, and generate reports, can be preserved for inspection or printing; 15. Control system: computer + control software, mass flowmeter, etc.

Standards According to the clause 9.6 & 9.7 of UL1685-2007, UL2556-2007

|

| Product Tags: lab testing equipment vertical flammability chamber |

|

AS1334.10-1994 Conveyor Belt Flammability And Flame Propagation Characteristics Test Chamber |

|

ASTM E1354 HEAT RELEASE CONE CALORIMETER WITH OXYGEN ANALYZER |

|

Building Materials ASTM D2843 Smoke Density Tester For Assessment Of Density of Smoke |

|

DIN 4102-1 ISO 11925-2 ( PLC ) Control Building Materials Flammability Ananlyzer |

|

Iso5660-12002 Cone Calorimeter For Testing The Heat Release Rate Of Building Materials |

|

ASTM E648 Flooring Radiant Panel Test ChamberFor All Kinds Of Flooring Materials |