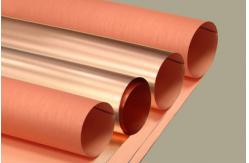

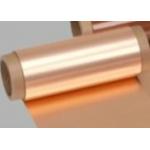

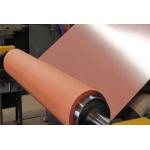

25um Thick Electrodeposited ED Copper Foil Roll Anti Oxidation

|

0.025mm Thick ED Copper Foil , Copper Foil 25 micron

Advantages 1. Good ductility and strong viscosity. 2. Low surface Oxygen

characteristics. 3. Good electrical conductivity and Shielding

Effect. 4. Good effectiveness on static discharge after grounding.

5. Excellent adhesion strength and thermal conductivity. 6. Roll or

sheet can be customized, custom made size and shape also

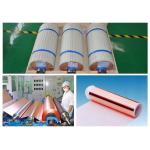

acceptable. Company Information JIMA has 20 years experience in copper foil industry, more than 27000 tons output yearly to meet the rising market requirement. In PCB, battery and shielding field, our copper foil leads the market as a material supplier. High quality product and sincere service is our fundamental to be existence and developing.

Copper Specification

ED Copper Foil Typical Properties

Copper Feature

The Production Flow :

Copper Foil Photos

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: electrodeposited ED Copper Foil Anti oxidation ED Copper Foil 25um electrodeposited copper foil | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Thickness 35um ED Copper Foil For Flexible Printed Circuit |

|

Red Or Gray 99.8% Purity ED Copper Foil for PCB Laminate Width 35um , 70um |

|

3 OZ Electrolytic Rolled Copper Foil , High Ductility Ultra Thin Copper Foil |

|

105um High Ductility Thin Copper Foil For Epoxy Board High Peel Strength |

|

High Temperature HTE Copper Foil , Elongation Electrodeposited 3m Copper Foil |

|

HTE ED Copper Foil High Temperature Elongation 12um Thickness For RFPCB |