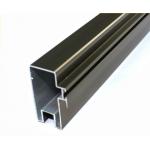

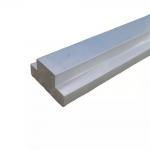

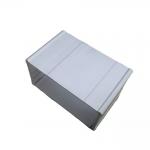

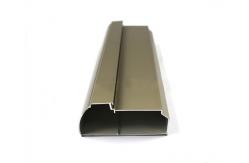

6061 cnc machining parts Extruded Aluminum Electronics Enclosure Specifiaction: | Description | 6061 cnc machining parts Extruded Aluminum Electronics Enclosure | | Material Thickness(t) | t=1.0 / 1.2 / 1.4 | | Material | Aluminum Alloy 6063, 6061 | | Annealing Treatment | T5,T6 | | Color | Green, Grey, Black, White, (RAL series)etc. | | Surface Treatment | Mill finish, anodized, powder coated, electrophoresis, sand balsting etc.and depend on customer’s demand. | | Shape | Square, Round, Flat, Oval, and according to customer's drawing. | | Length | Normal length=6 m | | Usage | Building, Production Line, Decoration, Industrial, Transportation, Door and window, etc. | | Package | 1. Pearl cotton foam for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. | | Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

Aluminum alloy building profile is the main structural material of

doors and Windows and curtain wall, widely used worldwide. Aluminum

alloy extruded profile (without surface treatment) has a single

appearance and is easy to corrode in humid atmosphere, thus it is

difficult to meet the requirements of high decorative and strong

resistance of building materials. In order to improve the

decoration effect, enhance the corrosion resistance and prolong the

service life, the aluminum profile generally has to be treated

surface. Therefore, surface treatment is an indispensable and

extremely important process of aluminum alloy construction. The surface treatment technology of aluminum profile is different,

and its process is different. According to the nature of the

protective layer and process characteristics, aluminum surface

treatment technology can be divided into anodic oxidation

treatment, anodized, electrophoresis, organic coating treatment

three categories, among them, the organic coating processing

includes powder coating, fluorocarbon coating and wood processing

|