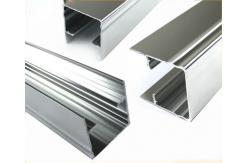

Chemically Polished Aluminum Angle Extrusion For Windows And Doors , ISO9001 approved

|

|

fabrication of aluminum windows and doors Polished Aluminum Profiles

Specifiaction:

The mechanism of polishing machining

The comprehensive process of polishing machining, plastic processing and chemical action. Is machining micro grits, friction, high temperature and crowded brush workpiece surface layer is plastic processing, polish media under the effect of temperature and pressure with the metal surface layer is chemistry.

Polishing

Polishing is a modification of the surface of the workpiece using flexible polishing tools and abrasive particles or other polishing medium. Polishing can improve the size precision of the workpiece or geometric accuracy, but in order to get smooth surface or bright luster for the purpose, sometimes also used to eliminate the gloss (extinction). Polishing is the process of smoothing the surface of the workpiece using abrasive and mechanical surfaces. Technically, polishing refers to the mechanical use of the machine to apply the abrasive to a loose piece of work. A more active process, which leads to a smoother, brighter surface finish.

How to polish/polish editors

1. Mechanical polishing

Mechanical cutting, polishing is to rely on material surface plastic deformation after removed by polishing the convex part of the smooth surface polishing method, commonly used article oil stone, wool wheel, abrasive paper, etc., with manual operation is given priority to, special parts such as rotary surface Face, can use the auxiliary tool such as the platform, the surface quality requirement is high can adopt the method that the method that USES super grind to throw. Ultra-precision grinding is made by using special grinding tools, which are in the liquid of grinding, which is tightly pressed on the surface of the workpiece, which is the high speed Turn movement. Using this technique, the surface roughness of the Ra0.008 mu m is the highest of all kinds of polishing methods. Optical lens molds are often used in this way.

2. Chemical polishing

The chemical polishing is a partially concave part of the substrate that allows the material to surface in the chemical medium, allowing it to be smoothed. The main advantage of this approach is that there is no need for complex equipment, which can be polished to a complex piece of work Polishing a lot of the workpiece, the efficiency is high. The core problem of chemical polishing is the preparation of polishes. The surface roughness obtained by chemical polishing is usually 10μm.

|

||||||||||||||||||||

| Product Tags: custom aluminum profile aluminium corner profile |

|

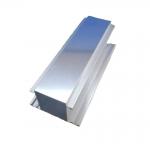

Machine Polishing Silver Oxide Aluminium Extrusions 6063 T5 Aluminium Profiles Building Materials |

|

Machine Polishing Silver Oxide Aluminium Extrusions 6063 T5 Aluminium Profiles Building Materials |

|

Anodized Mirror Polished Aluminum Profile For Kitchen Cabinet Wire |

|

Casement Window Frame Cnc 6063 Polished Aluminium Profile |

|

Cnc Machined Silver Bright 6063 Polished Aluminium Profile |

|

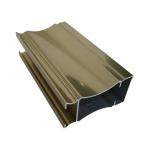

6063 OEM Customized 6m Machined Golden Polished Aluminium Profiles for Building Decoration |